HEAT PUMPS

Pursuing environmental sustainability means guaranteeing our future as well as the future of the planet. The issue of emissions has therefore become increasingly compelling in recent years. In spite of this, industrialised and developing nations are still struggling to reach an agreement. For now the targets set (and hoped for) are more ambitious than in the past: a 30 % reduction in greenhouse gases by 2030, to reach over 50 % by 2050.

When it comes to emissions, household air conditioning was the first area subjected to intense criticism, and several parties have been searching for solutions to help improve the energy usage of buildings and to promote the use of renewable energy sources. Legislation and incentives encourage the replacement of fossil fuel boilers with heat pumps: machines capable of drawing thermal energy from a low-temperature room and transferring it to another room with a higher temperature. In Italy these are already incentivised for almost all new-build properties.

A significant problem remains, however: how to replace the large number of boilers already installed in our property market with heat pumps?

Heat pump manufacturers have risen to the challenge, making them increasingly efficient and financially accessible in order to encourage more widespread application.

Caleffi also believes in this revolution and invests in research, development and processes for creating specific components used in this type of system, with the aim of making the role of designers and installers easier during the transition phase.

The CALEFFI range for heat pumps

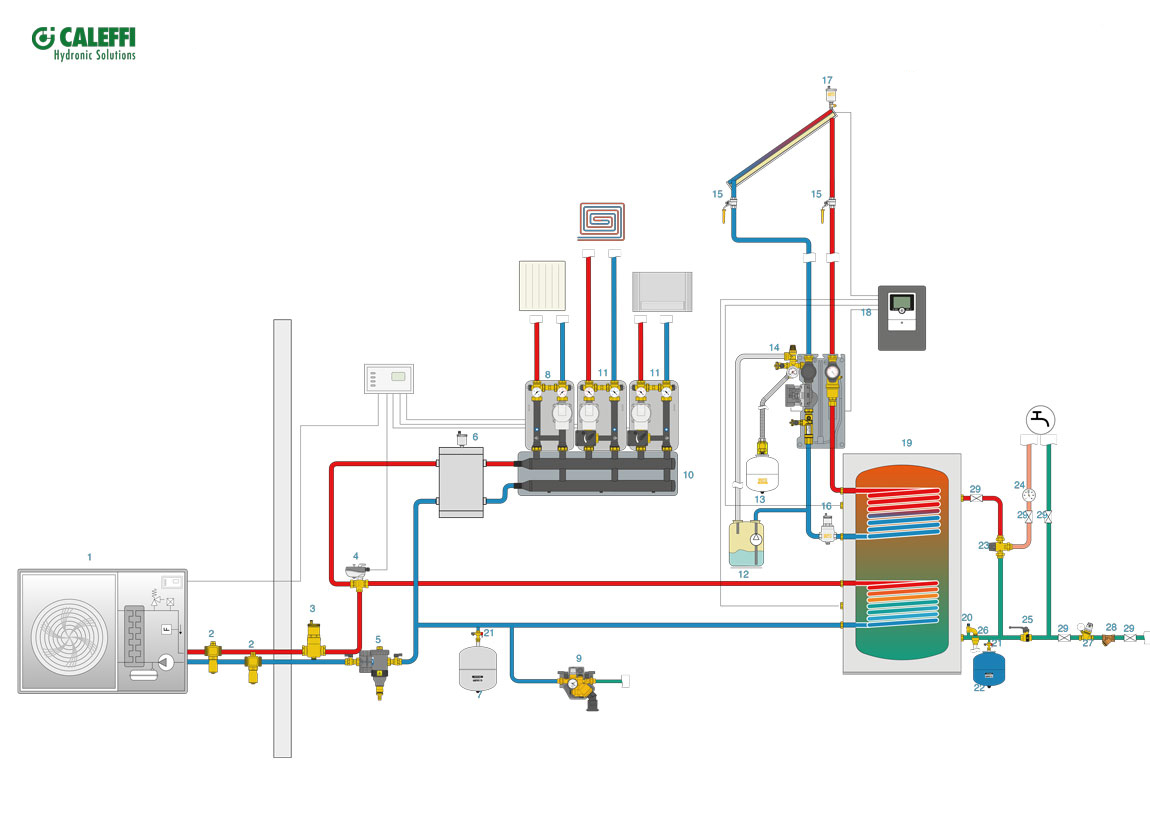

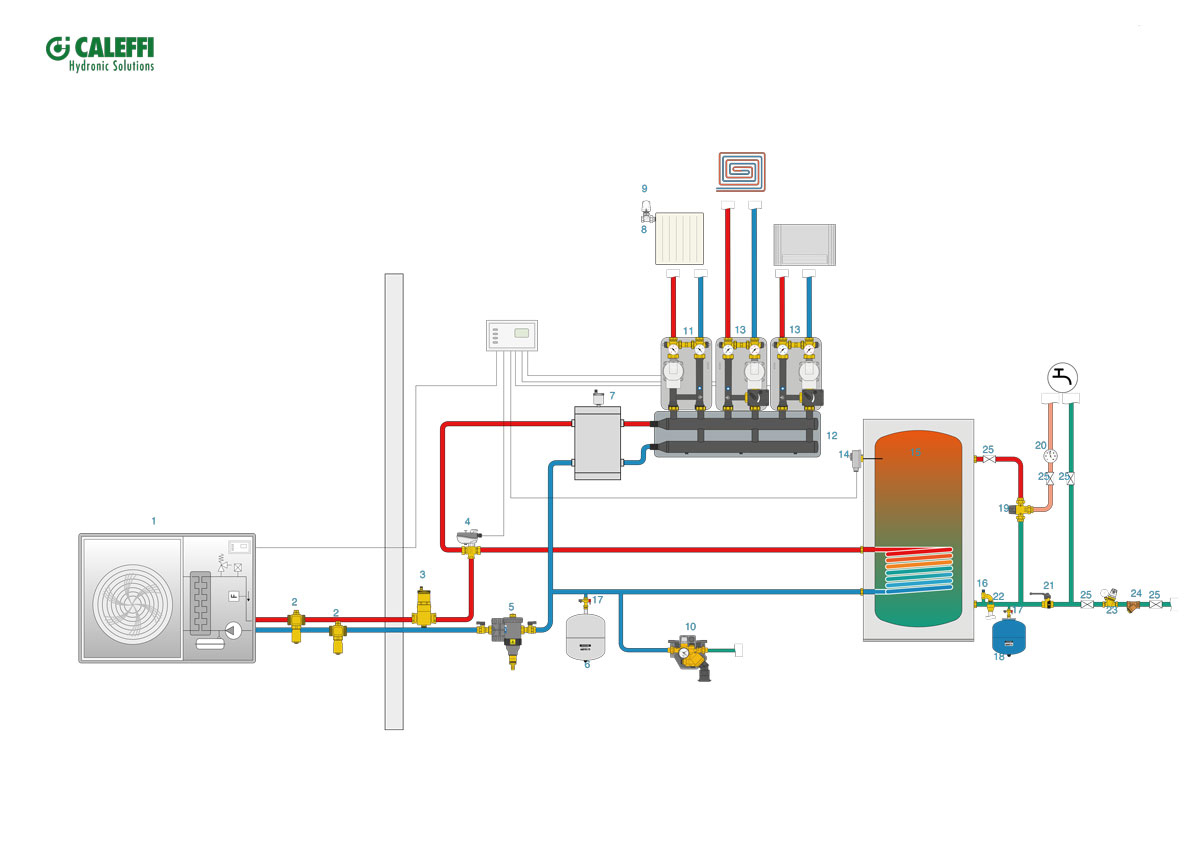

The typical diagram of a heat pump system, as illustrated above, requires the application of several components which are fundamental in ensuring it runs optimally.

Today, heat pumps are changing the hydraulic heating and domestic water system sector from a green perspective. We have always been great supporters of renewable energy sources and, as such, we have developed a full range of products to ensure the correct operation, efficiency and safety of the new heating and cooling systems.

THE HYDRAULIC SEPARATOR

In systems which anticipate the use of a booster pump, we suggest separating the primary and secondary circuits using a hydraulic separator. This is to avoid interference between these circuits due to variations in the flow rates and head generated by the circulation pumps.

How do hydraulic separators work?

THE DIRT SEPARATOR STRAINER

As far as water treatment is concerned, a heat pump system behaves like a traditional boiler system and is subject to the same legal requirements (in Italy, the Minimum Requirements Decree of 2015). Keeping the water quality suitable for constant circulation helps to achieve an energy saving of 8 % for the system. How? By installing a dirt separator or a magnetic dirt separator strainer and proceeding with compulsory chemical conditioning using the specified additives.

The multi-function device consists of a dirt separator and a cartridge strainer arranged in series. The dirt separator separates the impurities in the water through the action of the internal element and captures ferrous particles through the action of two magnets. The cartridge strainer separates off the impurities, by means of the mechanical selection of particles according to their dimensions with a specific filtering metal mesh. This is how maximum particle separation efficiency is achieved at the very first passage.

MOTORISED DIVERTER VALVES

These allow management of the flow between the air conditioning system (heating and air conditioning) and the domestic water preparation system.

MOTORISED DIVERTER VALVES 638 SERIES

THE INSTRUMENT HOLDER

For heating systems with an air vent, composite safety relief valve and pressure gauge.

THE BY-PASS VALVE

This is used in systems where widely varying flow rates may operate. It ensures a flow recirculation proportional to the number of valves being closed, while limiting the maximum differential pressure value generated by the pump.

DIFFERENTIAL BY-PASS VALVE 519 SERIES

THE ANTIFREEZE VALVE

This allows the circuit medium to be drained when its temperature reaches an average value of 3 °C, thereby preventing ice from forming in the circuit of a system with a heat pump and avoiding potential damage to the machine and the pipes.