DIRTMAGSLIM®

We have been introducing the brand-new DIRTMAGSLIM®

DOWNLOAD THE SALES SHEET

A NEW DIRT SEPARATOR - ITS BACKGROUND

A NEW DIRT SEPARATOR - ITS BACKGROUND

For the past few years the economic situation throughout Europe has been severely limiting the number of new building construction projects and, consequently, the number of new heating and airconditioning installations.

At the same time we see a concerted drive also in legislative terms to promote replacement of legacy systems with modern condensing boilers. This is where new DIRTMAGSLIM® comes into the picture: if, as occurs in the majority of cases, the project involves replacing the boiler and installing thermostatic valves, installers are hampered by their very limited possibility to modify existing components of the system. As an initial palliative measure the system can be accurately flushed, but this action in no way prevents the continued contamination of the medium with ferrous and non-ferrous particulate originating from metal radiators and mild steel piping - a problem that tends to be aggravated by the increasing age of the system. Such impurities can have extremely deleterious effects on the boiler, primarily affecting:

- Variable speed circulators

- Water/flue gas boiler exchangers

- DHW side exchangers

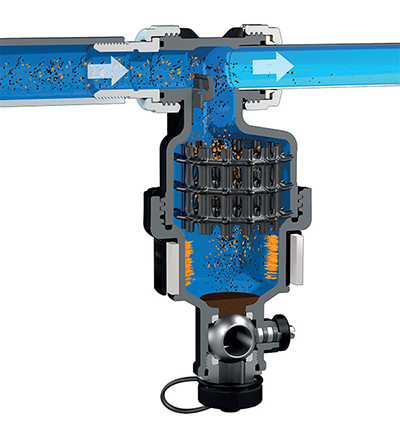

This results in need for magnetic dirt separators, i.e. devices capable of intercepting impurities in the system by exploiting the physical principle of precipitation due to gravity. The internal element, composed of reticular surfaces arranged in radial pattern and designed to promote the separation of impurities, offers low flow resistance and, unlike conventional mesh strainers, it does not lead to a gradual rise in head losses. Finally, the integral magnetic effect helps to separate and collect ferromagnetic particles of 5-10 micron in size.

Unfortunately, the physical space required to install a component of this type is frequently lacking. The conventional alternative solution involves installing a Y-strainer on the return line from the system to the boiler. While it is true that this component overcomes the space limitation, without correct maintenance rising head losses over time will produce an unjustified increase in the amount of electrical power required for circulation of the thermal medium.

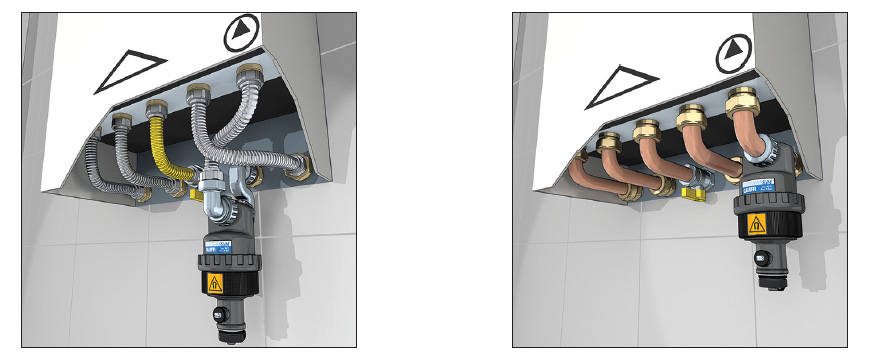

The new compact magnetic DIRTMAGSLIM® dirt separator is the perfect solution for installation in very confined spaces. If the new boiler connections are aligned with the wall connections – a rare occurrence in renovation projects although the norm in new installations – the connection is made as shown in the following image.

If a new boiler is installed in place of the existing one, the configuration of the connections will almost certainly be different: in this case the connections are made using flexible pipes. Also in this situation the DIRTMAGSLIM® dirt separator can be installed in the optimal position.

The DIRTMAGSLIM® magnetic dirt separator removes and collects impurities present in the circuit thanks to an internal deflector located in the medium flow.

This device creates turbulence in the medium that helps to transfer impurities to the decanting chamber where, thanks to the low medium velocity, the particles are captured and unable to return to the circuit. This operating principle makes it possible to keep the head loss inside the device to the minimum. Separation efficacy is enhanced by the presence of an external magnetic collar.