Case Study: Fabrica and Caleffi for Coop Reno

The design.

Politecnica and Fabrica have been working together to design the new Centro Direzionale (Business Centre) for Coop Reno, a project which has already come to represent the innovative spirit which Coop Reno has been promoting in the area for many years. A Business Centre organised according to the principles of sharing and gathering together, designed to develop over time from a functional point of view, in complete harmony with the environment and its future users. The plot of around 19,000 square metres, situated on completely free and level land, can be found the edge of the Poggio Piccolo industrial site in the municipality of Castel Guelfo di Bologna.

“A different kind of Green”: the visual representation of the Project, researched and organically inserted into the setting, enhances the rural and environmental aspects of the area. A soft and organic curve extends over the plot, becoming a thoroughfare that is symbolically identified with a plant sinking its roots into the surrounding roads, so that it can then grow freely in the green area, following the typical patterns of natural evolution.

Three of the four new buildings making up the plot are connected by a platform roof extending the length of the path designed for users, offering shelter and generating a system which combines architecture and furnished green spaces.

More specifically, in terms of the main buildings, the administrative centre covers a surface area of 3,800 square metres over 4 above-ground floors, and features an open-plan design to guarantee the utmost flexibility in terms of internal distribution. The ground, first and second floors accommodate high-quality workplaces such as: office spaces, meeting rooms, relaxation areas and service rooms.

A covered link connects the administrative building to the new 260-seat Auditorium. The auditorium will mainly be used by the occupants of the administrative centre, but will also offer the option of opening up to the public for specific events. There is a buffet area with special food and beverage preparation rooms on the first floor, and a large terrace overlooking the park.

A multi-purpose building, a warehouse building and a technological building will complete the plot.

The systems.

The systems serving the buildings, with particular reference to the administrative building and the auditorium, were created and developed in accordance with energy efficiency criteria, anticipating the use of high-quality components, materials and equipment, as well as flexibility in the use and regulation of these systems, even in the face of new and altered requirements linked to the Covid-19 pandemic.

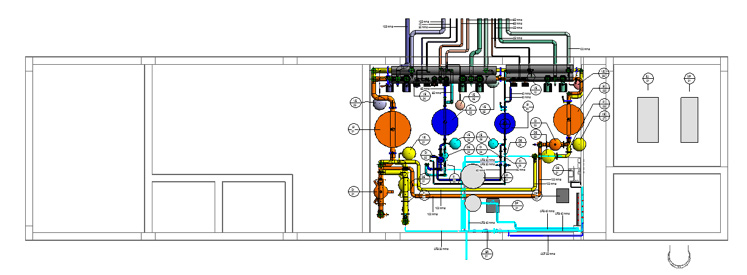

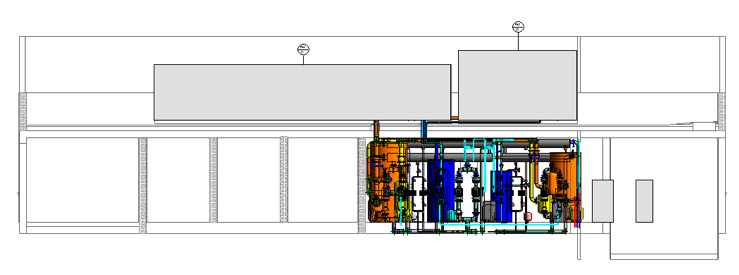

To be more specific, the buildings are served by a hydronic fan-coil system and a primary ventilation system. Domestic water distribution is controlled centrally to guarantee the quality of the treatments, while rainwater is collected and distributed to serve the rinsing rooms.

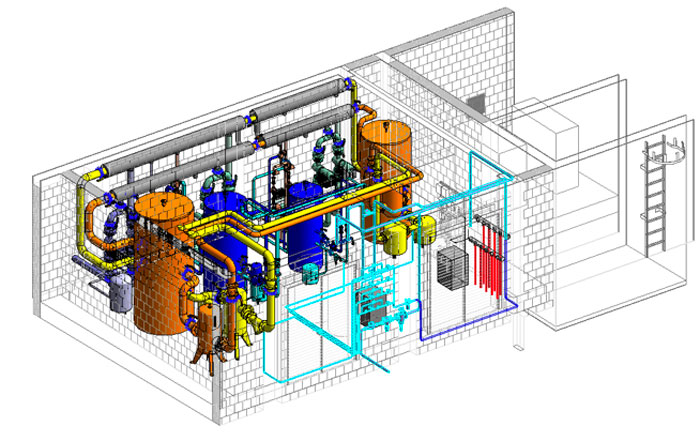

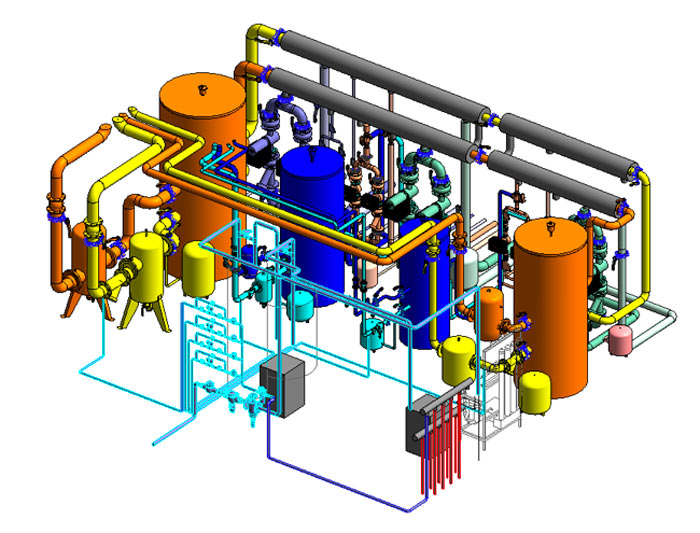

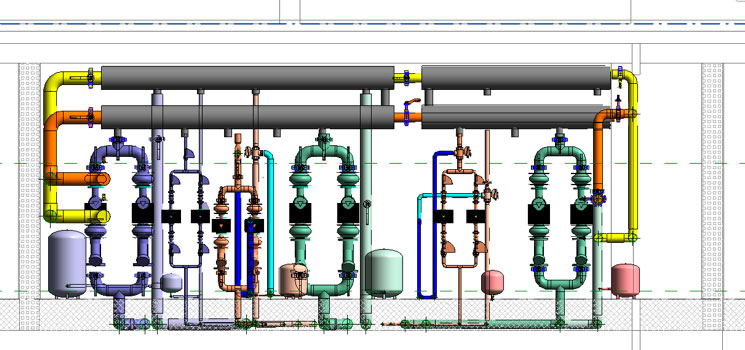

To optimise spaces and future maintenance procedures, it was decided that a specific building should be created to accommodate the mechanical, electrical and fire prevention systems serving the main buildings and, more generally, the plot as a whole.

Use of BIM tools (Fabrica).

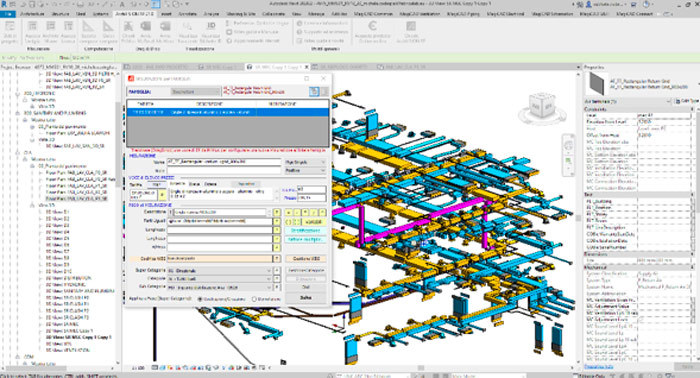

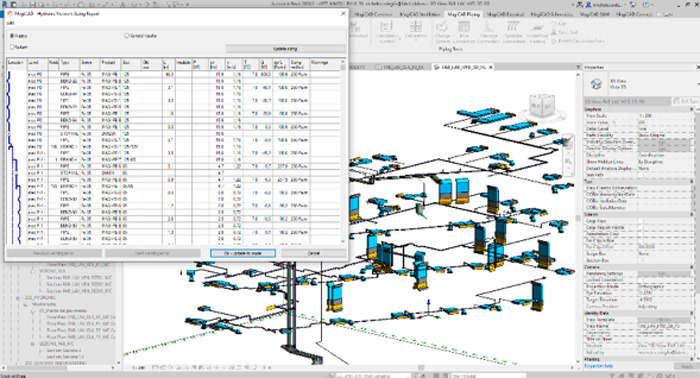

Politecnica and Fabrica use BIM methods and tools for their design activities. The journey consisting of activities linked to contracts, to structured moments associated with research and development and to the possibility of exchange and discussion has helped to make the use of BIM Authoring tools a stable, consistent and efficient process. The Case Study design was actually created entirely within the “BIM flow”; in fact the authoring software, complete with various plug-ins, was used to perform all calculations relating to the sizing of pipes and air ducts, and allowed dynamic implementation of the full computation.

It is plain to see how using BIM tools leads to an ever-increasing interest in the “IT side” of the models, which is aimed at increasing performance in the design phases, during the tender procedure and throughout the subsequent construction and “as built” stages. Continuity in the use of the model goes even further, to serve the life cycle of the entire building-plant system and becoming the new cornerstone of the facility management system.

Ultimately it is evident how, side-by-side with capable and informed design work – where the designer continues and will continue their own role, regardless of the methods and tools used – the IT aspect linked to the connected models (and consequently to the objects used in their construction and population) is becoming extremely important.

The virtual objects, or rather the BIM families of the components, are now chosen by the designers as a central element in relation to the procedural models set out by the BIM method, with a huge impact on quality, timescales and all activities relating to the completion of the design phases.

The partnership.

This Case Study immediately appeared to be an excellent opportunity for collaboration and dialogue between two BIM design companies such as Politecnica and Fabrica, and one of the leading global producers of system components such as Caleffi.

Caleffi, as a manufacturer, offers the opportunity of improving the virtual objects for its products, in order to meet the requirements of those who use them.

The designers on the other hand, as the actual users, need to share the necessary information as much as possible to ensure that these objects are increasingly useful and integrated into the BIM flow.

The synergy created during this collaboration touched on several in-depth themes and points as it was, for Fabrica and Caleffi, the first real opportunity for such a specific discussion.

In drilling down into the smallest details, Caleffi has been able to improve its understanding of the needs of a BIM user and capitalise on them, by observing the whole flow applied to a real project (“flow” should be interpreted as the sequence of all hidden steps behind the creation of a central heating system). It started with a one-line diagram and progressed through to the metric calculation, via the positioning of all product families inside and outside the dedicated technical room.

The close partnership experienced on a daily basis by the three companies has resulted in many strides forward.

By closely monitoring the positioning, use and application of the virtual objects created by the company, Caleffi succeeded in implementing the new specifications and parameters required by the group of designers in order to improve the objects and fully integrate them into all phases of a BIM project.

Dynamic computation

Dynamic calculations and sizing procedures

On the other hand, Politecnica and Fabrica were able to observe the actual work and investment behind the creation of these products on the part of the manufacturer, and to note on which points they can intervene.

Because of all this, the three companies have begun a new journey towards optimising all the steps in the BIM flow.