At first glance, piping a hydraulic separator - which has 4 connections - can be a little confusing. Here is an easy-to-remember guideline to assure proper flow patterns and high performance from your Caleffi Hydro Separator, HydroCal™ or Sep4™.

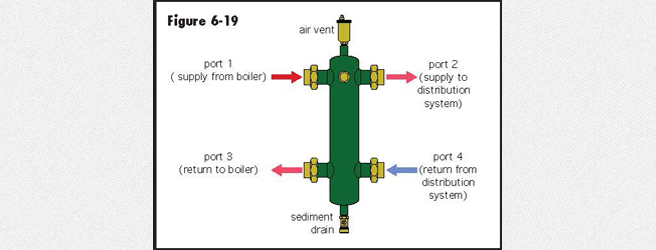

Keep hot on top, cold on bottom. For a heating application this means connect the boiler hot water supply to one of the top connections and connect the secondary hot water supply to the opposite top connection. The boiler return connection is on the bottom, on the same side of the separator as the boiler supply. Across from the boiler return is the secondary return. Caleffi separators are not flow-directional; you can have the primary loop on the left and the secondary loop on the right, or vice versa (refer to Figure 6-19 from idronics™ 15: Separation in Hydronic Systems).

For a chilled water application, the hot on top, cold on bottom guideline still applies. Connect the chiller water supply to one of the bottom connections and the secondary chilled water supply directly across. The warmer returns will be on the top.

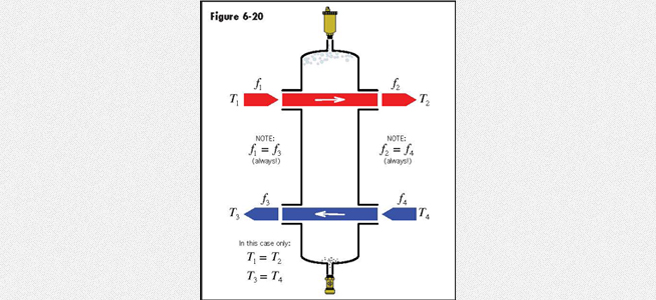

Another way to look at it is this same guideline is this: if you have clockwise flow on the primary side of the separator, make sure you have clockwise flow on the secondary side. Counterclockwise in the primary, counterclockwise in the secondary. If piped such that flow directions are opposite, undesirable mixing will occur in the barrel of the separator which will affect the secondary temperatures and primary return temperature (refer to Figure 6-20 from idronics™ 15: Separation in Hydronic Systems).

Hot on top will also assist in air separation; water's ability to contain air bubbles decreases at higher temperatures. Escaping air bubbles are then directly under the air vent where they are removed from the system.

Hot on top, cold on bottom piping for separators also assures maximum temperature differential (delta T) for the primary generator (boiler or chiller), which is highly desirable.

What are your comments? Thoughts? Let us know!

Kevin

I was told by a guy with 35 years of hydronic heating experience that if you pipe the supply from the boiler to the bottom of the hydraulic separator and have the return on the top, but have the supply with pump to the field on the top port of the hydraulic separator and the return from the field on the bottom, that it would work just fine. He said that there is not enough mixing going on in the separator to effect the temperature by more then a couple degrees. Any thoughts on this?

The reason I am asking is because the idronics manual says to only pipe supply to top and return to the bottom. Sometimes the piping would be nicer looking to the eye if i could bring the supply into the bottom.

Thanks, Brian

In reply to I was told by a guy with 35 by Brian Stern

Brian, if I am understanding your question properly, piping a hydraulic separator the way you have described would cause a pretty big problem. When you’re putting the boiler piping into one side of the separator with supply on bottom and return on top and the system into the other side with supply on top and return on bottom you will be forcing the boiler supply and system return to mix before going to the top boiler return or the top system supply. When this happens you will essentially be mixing down the temperature of the water going to your system and mixing up the temperature of the water returning to your boiler. This would lower the capacity of your heating system for sure, but as to how much, I can’t be certain.

I’m glad our literature is keeping everyone on their toes and questioning what may not be best practice!

This item, in my opinion, is the best in the business. I have used these on several projects I have installed and I continually recommend these when I am selling my boilers or pumps. Easy to install and bulletproof....what more could you ask for? Thank you, Caleffi!!

In reply to This item in my opinion is by Bruce drummond

Bruce,

We sure appreciate you taking the time to post your comments!

I have one new boiler and a large heating system with many zones but only one pump for the entire heating system do i need a buffer tank for this application. The boiler is moving about 300GPH, I ordered a tank i hope i am doing this right. with another pump. noet one boiler one zone and 4 risers

M Wasoff

In reply to I have one new boiler and a by Marvin Wasoff

Marvin:

Thanks so much for your questions and so sorry for the late reply.

The need for hydraulic separation and/or a buffer tank is going to depend greatly on your system. Many boiler manufacturers will require a certain flow through their product and if you'll be using the boiler in a system with many zones that will turn on and off as needed, hydraulic separation will be a requirement. Because your system will end up with varying amounts of flow the hydraulic separator will be sure to allow your boiler to have the correct flow that it needs at all times.

In many systems, a buffer tank (hydraulic separation with added capacity) is a great idea. In conditions where only one small zone requires heat it will cause the boiler to short cycle (even modulating boilers) and greatly reduce efficiency. By adding a buffer tank, you not only get hydraulic separation but you add volume to the system and this will lengthen the run times of your boiler and increase efficiency.

Be sure to keep an eye out for our next edition of idronics, it will be covering the top of thermal storage and buffer tanks! Link below.

http://www.caleffi.com/usa/en-us/technical-magazine

If you have any other questions please feel free to contact your local distributor, manufacturers rep or us directly at (414) 238-2360.

My 548 separator was installed with the hot on the bottom.

How much is this costing me?

In reply to My 548 separator was by Bob Glanville

It's hard to say just how much it's costing you, Bob. Probably not much. Some heat rise in the barrel of the separator could mean your boiler return temperature would be a little warmer than it should be, resulting in lower delta T and lower efficiency. However, that's assuming the same flow rate in your primary and secondary, which is not common. If your secondary flow is greater than your primary flow, you'll have downward flow in the barrel of the separator and your boiler return temperature will be the same as your secondary return temperature. So that is OK.

Perhaps the more important issue with your configuration is reduced air separation effectiveness at the automatic vent at the top of the separator. Hot water more readily gives up entrained air than cold water does, so it will take longer to remove air from the system the way you have it piped.

Take a look at Caleffi idronics issue 15 for more information on separation principles.

I wonder if hydronic separator has is a minimum distance from the flange/press fitting to the nearest elbow. For the closely spaced tees the distance on primary side is 8x and 4x. Is there such thing for the SEP4? Can I have an elbow 2x from the flange/press fitting?

In reply to I wonder if hydronic by Kirill Jacobson

Kirill, We get this question from time to time. If the separator and pipe sizing is correct, because of the larger barrell in the separator, there is little to no pressure drop so distance from the separator to pipe elbow does not affect the performance. Your installation with an elbow 2X the pipe diameter from a flange or press fitting will be not affect the performance.

I purchased the Hydro Sep4 for a 3 zone/3 pump system. Appreciate the 2 year old answers. These saved me some time and anxiety. I have a question about the height from the floor. I have a tight space so I'm trying to use it wisely. How low can I mount the hydro sep4 and be able to service the dirt/mag separator at the bottom?

In reply to I purchased the Hydro Sep4 by Tim O

Tim, The purge port to flush the debris from the SEP4 is at the bottom. Typically you would want to put a bucket under it to do a power flush. It would be recommended to have it high enough to be able to access the port to power flush it unless you attach a hose to route the purge point to a flush location.

How can we calculate the size of the hydraulic separatorś barrel?

In reply to How can we calculate the size by Ali

Ali, In general the hydraulic separator body is 3-4 times larger than the connection size. If you need specific details on a model you can contact Caleffi tech support 414-238-2360 and we can assist you.

We have a Caleffi separator just installed in a hydronic radiant heating system with two floor heating secondary circuits and one DHW heating circuit. We now find that when there is a call for DHW, the system also sends hot water backward into the two floor heating return paths (no pumps are on as thermostats are off on those circuits). It appears the hot flow from the boiler in the primary circuit is moving across and into the cold return on the distribution side of the separator. Is there any way to reduce or eliminate this type of flow ... or is it even perceived to be a problem? Prior to the installation of the separator we had closely-spaced T's to hook the secondary circuits to the primary. Thanks in advance for any wisdom you may have on this.

In reply to We have a Caleffi separator by Art Monk

Please forward a drawing and photos of your system to techsupport.us@caleffi.com. I would need to see how your system is piped to assist with troubleshooting the performance.