A Y-strainer is an in-line filter for hydronic systems. As the strainer starts trapping dirt, resistance to flow (pressure drop) will increase. Measuring the pressure drop across the strainer while the system pumps are running, will indicate how plugged the strainer is.

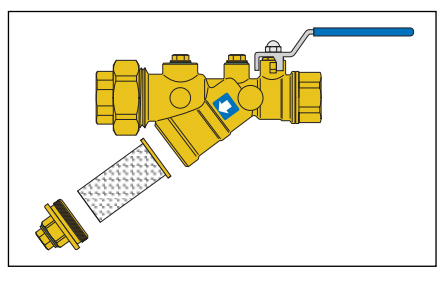

The Caleffi 120 Series Y-strainer has two 1/4" NPT female pressure tap connections - one upstream and one downstream - which are used to measure the pressure drop across the strainer. To determine when the strainer needs to be cleaned, first take a differential pressure (DP) measurement between the pressure tap connections when the strainer is new and the system is running at design flow. Use this DP as your "clean strainer" reference. In general, when the pressure drop across a y-strainer gets to about 5 or 6 psi differential, it's time to clean it.

Never let it get too plugged; for example, more than 10 psi. Since strainers are inline devices, increased differential pressure means increased system head loss and increased pump power, all which lead to lower system performance and higher operating costs.Take DP measurements frequently during startup of the system and then stretch out the frequency as part of a normal maintenance program.

A convenient way to temporarily measure the pressure drop across the Caleffi 120 Series is to buy the models with PT taps pre-installed on the pressure ports. Use a portable, wet-wet differential pressure measuring device with gauge adapter plugs to take readings. Permanent indication is nice; there are companies that make wall-mount wet-wet differential pressure gauges that you can connect directly to the 1/4" NPT ports on the Caleffi 120 models without PT plugs.

If connection to a building automation system is required, find a wet-wet differential pressure transmitter that will connect directly to the 1/4" NPT ports and has the analog output signal the BAS needs.

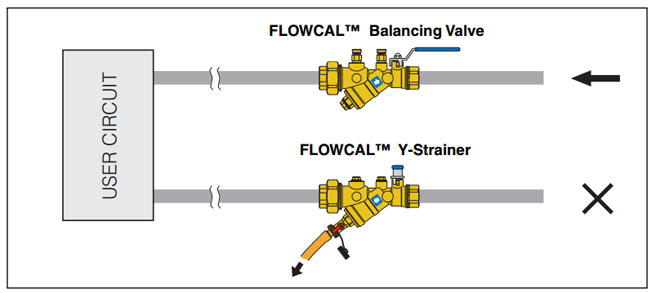

Cleaning the 120 Series is easy, especially if there is a 538 Series blow-down valve installed on the drain port (recommended). Usually, a blow down through the 538 will sufficiently clean the strainer. The strainer can also easily be removed for inspection and cleaning if necessary. Check out the 120 Series Installation Instructions for all the details.

we have four solar panels on the roof of an aquatic building, are drain lines required and can you please send me any specs on this matter. my name is Julio Castro and my contact number is 915-493-7323. thank you

Julio, that will depend on your local code requirements and/or standard practice for your region. It's not a product-specific issue and none of our literature will address your question.

What's the usual product life of a Y-strainer under typical commercial building usage? I'm referring to the entire Flow-Cal 120+538 series as described in this article, not just the filter itself.

Thank you!

Hi. What will happen if y strainer not cleaned ?

In reply to Hi. What will happen if y by Kashiff ahmed

Kashiff, To answer both of your questions, if the Y-strainer is not cleaned it could restrict flow and cause failure in the product. The life of the Y-strainer comes back to how it is maintained and water quality. It is a stainless steel mesh filter that is robust but like any product is affected by water quality and maintenance.

Where can I purchase screen strainers for the Y-strainer? I have a red one that needs to be replaced. 4 1/4" long flange on one end

In reply to Where can I purchase screen by Carol Edwards

Carol, We have our 120 series Y-strainer with union connection and isolation ball valve. We do not have replacement screens, they would be removed and cleaned or replaced.

Hi,

we are designing some strainers for our project and our question is

what is allowable clogging for setting alarm of strainers?

please specified that based on standard (if applicable)

In reply to Hi, by Hossein Kahrizi

Strainers will catch and remove debris in the system. Ideally, you want to flush and clean to get the debris out. The more clogged the strainer becomes the larger the pressure drop becomes and can affect system performance. If you have a lot of debris in the system you may want to consider a system dirt or magnetic separator.