Controllable, reduced pressure zone backflow preventer.

Product Description

Controllable, reduced pressure zone backflow preventer.

To be coupled with flat counterflanges EN 1092-1.

Upstream of the backflow preventer is mandatory to install a strainer 579 series.

BA type.

Certified to EN 12729.

Technical data

Differential operating pressure:

14 kPa

Medium temperature range:

5–60 °C

Nominal pressure:

PN 10

Finish:

coated

Material:

cast iron

Certifications

Download

Drawings and specifications

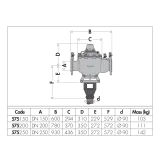

| Part number | Connection | ||

|---|---|---|---|

| 575150 | DN 150 (EN 1092-1) PN 16 |

||

|

3D models

Tender text

Controllable, reduced pressure zone backflow preventer.

To be coupled with flat counterflanges EN 1092-1.

Upstream of the backflow preventer is mandatory to install a strainer 579 series.

BA type.

Certified to EN 12729.

Connection: DN 150 (EN 1092-1) PN 10. Differential operating pressure: 14 kPa. Medium temperature range: 5–60 °C. Nominal pressure: PN 10. Finish: coated. Material: cast iron.

SCIP code

CODICE IN FASE DI ANALISI

|

|||

| 575200 | DN 200 (EN 1092-1) PN 16 |

||

|

3D models

Tender text

Controllable, reduced pressure zone backflow preventer.

To be coupled with flat counterflanges EN 1092-1.

Upstream of the backflow preventer is mandatory to install a strainer 579 series.

BA type.

Certified to EN 12729.

Connection: DN 200 (EN 1092-1) PN 16. Differential operating pressure: 14 kPa. Medium temperature range: 5–60 °C. Nominal pressure: PN 10. Finish: coated. Material: cast iron.

SCIP code

CODICE IN FASE DI ANALISI

|

|||

| 575250 | DN 250 (EN 1092-1) PN 16 |

||

|

3D models

Tender text

Controllable, reduced pressure zone backflow preventer.

To be coupled with flat counterflanges EN 1092-1.

Upstream of the backflow preventer is mandatory to install a strainer 579 series.

BA type.

Certified to EN 12729.

Connection: DN 250 (EN 1092-1) PN 16. Differential operating pressure: 14 kPa. Medium temperature range: 5–60 °C. Nominal pressure: PN 10. Finish: coated. Material: cast iron.

SCIP code

CODICE IN FASE DI ANALISI

|

|||