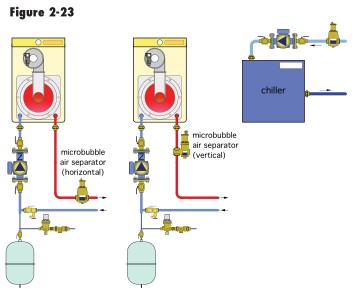

The best place to locate an air separator in a hydronic system is where the water temperature is high and the pressure is low. The solubility of the dissolved gases in the water is lowest at these conditions. For a heating system, the ideal location is at the outlet of the heat source. For chilled water systems, locate the separator in the return to the chiller. In wall-hung boiler installations, it is convenient to mount the air separator in the vertical hot water supply pipe, as shown in the figure below.

Of course, not all jobsite piping arrangements allow ideal installation of the air separator. Remember, an air separator is a multi-pass device and over time it will "scrub out" air and can bring the dissolved air content down to less than 0.5% of system volume. In that condition, the water will provide excellent heat transfer (air is an insulator, not a good conductor), and virtually eliminate noise (air makes noise in a hydronic system). Also, and maybe most important, removing air reduces corrosion. Corrosion destroys moving parts such as valve packings and pump seals and will foul heat exchangers, all bad news.

An air separator is cheap insurance against premature system failures and unhappy customers; read more about air separation (and dirt separation) in Caleffi idronics issue #15. Also, check out the whole family of Caleffi 551 Series DISCAL air separators and 546 Series DISCALDIRT air/dirt separators. Contact us with any questions you have; we are glad to help you succeed!

can the air separator be installed below the level of the pipe? that is level of the pipe is at 3m from floor then pipe goes to the air separator inlet at level 0.5 m from floor, out to the separator outlet at the same level then up again to pipe original level of 3 m. Can this be done? what is the disadvantage?

Thank you.

Eugene

Of course an air separator should be mounted where it will be most effective, in the boiler supply piping, on the low pressure side of a pump, and preferably at a high point in the system where the air will tend to be. The separator will remove whatever air passes through it, no matter where it is located in the system, so you can mount is as you describe but it may be less effective.

How is the efficience of air separator at inlet of chilled water pump compared with air vent (air release valve) installed at several high level location of piping system?

Regards,

BT

Air vents should be mounted at any point in a piping system where an air bubble could form. An air separator is an in-line device that removes entrained air (microbubbles) that is moving with the flow of the fluid; they are different products for different purposes and you can't really compare efficiency between the two. All hydronic systems should have air vents (wherever needed) and an air separator.

If I must install the air vents at the point with higher temperature and lowest pressure, could I install the air vents near to pump suction in order to substitute the air separator?

In reply to If I must install the air by Jose Parra

Jose,

The air vent would typically be installed at the highest point because it is counting on air to migrate into the vent, raise the float and is then removed. The air separator on the other hand is installed at the suction side of the pump because the coalescing mesh will separate the air bubbles from the water as it is drawn through the separator allow them to rise to the top of the and be removed. Without the mesh or something to separate the micro-bubbles the air vent would not be as effective.

Dan Firkus

Caleffi North America

In reply to Jose, by dan_firkus

Dan,

Our system circulator is downstream of the boilers. The 2 mid efficiency boilers each have a pump. Would it be better to put the air separator before the main circulator, where the water is coolest though, or after the boilers, and all the pumps, where the pressure is relatively higher?

In reply to Dan, by Bruce

Bruce, You will want to locate the air separator on the supply side of your boiler wihere the temperature is the highest and on the suction side of your pump.

In reply to Bruce, You will want to by dan_firkus

Right, that's what's not possible. The suction side of the pump is on the return side. The hot water is on the supply side. Which is more important, low pressure or high temperature - if we have to choose?

In reply to Right, that's what's not by Bruce

Bruce, See attachment. The separator at the supply out of the boiler where water temp is the highest and the pump on the return pumping through the boiler still locates the separator on the suction side of the pump so that is an acceptable installation.

There seems to be a discrepancy between the text above "the best place to locate an air separator in a hydronic system is where the water temperature is high and the pressure is low" and the diagram above. The diagram shows the air separator at the high pressure location - after the pump. Can you please clarify.

Our intent is to install air separator in this sequence: boiler, expansion tank with air filler and drain, air separator and then circulator. Can you please comment.

In reply to There seems to be discrepancy by Zoka Zola

Hello, your location of the air separator and pump is correct, you would want your air separator before the pump or on the suction side of the pump. The fill and expansion tank can be installed below the air separator on a smaller system or on a larger system we see them installed on the return side. The photo above shows the air separator on the supply side and the pump on the return pumping throught the boiler. The boiler provides the pressure drop which will place the air separator on the low pressure side with the pump after it pulling through the separator.

In reply to Hello, your location of the by dan_firkus

So Caleffi always recommends their air separator on the suction side of a pump?

In reply to So Caleffi always recommends by Steve

Steve, When locating the expansion tank on bottom of the separator you will want to have the pump after the separator pumping away so you do not preload your expansion tank. The air separator has a large body that provides a good drop in velocity that allows the internal coalescing mesh to separate the microbubbles from the water. It will perform better with the pump downstream from the separator.

Underfloor heating with a boiler how many automatic air vent valve can I install and best location

thanks

Dan

In reply to Underfloor heating with a by Dan

Dan,

You can install multiple auto air vents into a system and they are usually installed at a highpoint in the system or the top of a riser.

My hot water circulation system is used more as a cold water purge system. User hits a button and a pump runs for about a minute for that section of the house. I have four pumps each at the end of a dedicated return from the four corners of the house. All four pumps then return water through a manifold to a single pipe to the hot water heater. I don't really want to buy four air separators to place at the suction of each pump and I'm wondering if there's any point in putting it on the single return line to the cold inlet of the water heater which I can make the highest point in the system. I really don't have a particular issue without the air separator but want to put one in for good measure and to eliminate any air after servicing and purging the system.

Greg,

It sounds like you may be working with domestic hot water. We do not have a separator available for use with that application. We do have our PlumbVent that low lead for a domestic water heating application, but that is an air vent not an air separator. If you need more information or want us to look at the details on your project you can email our tech support at techsupport.us@caleffi.com.

Thank you,

Dan Firkus

does it matter how close the air separator is to my pump.

In reply to does it matter how close the by Nick

Nick, When locating your air separator it is important to have it located on the outlet side of your boiler and suction side of the pump. The pump can be directly after the air separator. For air separation I would recommend our 551 Discal. You can also find more information on hydraulic, air, dirt and magnet separation in issue 15 of our Idronics or in our Coffee with Caleffi webinar.

Can one utilize two air separators? The pump is inside my Baxi Luna boiler- can I put an air separator on both the outgoing water line and the return water line?

And install Both of them above the level of the boiler (at the ceiling height) ?

In reply to Can one utilize two air by eric baum

Eric, Typically you would install one air separator and that would be located on the supply out of the boiler and on the suction side of the pump. You will want to varify but looking at the Baxi Luna boiler the internal pump appears to be on the return side pumping through the boiler. If you are piping this primary/secondary, the air separator could be located on the secondary circuit, supply before the pump. You could locate a second air vent at a high point in the system for additional air removal.

What causes water to leak out of an air vent? And, how do you prevent the water leak in the air vent in the future?

In reply to What causes water to leak out by Richard

Richard, Typically when water leaks from the air vent it is a sign that there is debris that has passed the flow and become lodged in the seat of the needle valve that allows air to escape. You may be able to remove the cover and float and clean that out. If you need, Caleffi offers a replacement cap and float. Our products are the most serviceable in the industry.

I've seen where an expansion tank is plumbed directly to the bottom port of an air separator. Doesn't the element in the air separator function similar to that in a dirt separator? What prevents dirt in the fluid stream from dropping out at the air separator element and entering the expansion tank? Thanks.

In reply to I've seen where an expansion by brian

Brian, The smaller brass air separators are ok to pipe the expansion below the unit. The larger steel models we do not recommend using that location to pipe the expansion tank too. If you have a really dirty system than I would not recommend that location for the expansion tank because the air separator could remove dirt into the expansion tank. The idea with the expansion tank and fill located below is because it is installed at a point of no pressure in the system.

In reply to I've seen where an expansion by brian

Brian, The smaller brass air separators are ok to pipe the expansion below the unit. The larger steel models we do not recommend using that location to pipe the expansion tank too. If you have a really dirty system than I would not recommend that location for the expansion tank because the air separator could remove dirt into the expansion tank. The idea with the expansion tank and fill located below is because it is installed at a point of no pressure in the system.

Our heating system is not working, it is a 3 storey house and heating only works at the top floor. We were advised a power flush and after the boiler was put to max all radiators but one were working. After that there’s a discharge from an overflow pipe and we switched off the heating. After we turned it on, we discovered that one of the radiators in the bedroom upstairs stopped working and other ones in the lower 2 floors don’t work either. We are advised by a plumber to remove the air separator. Where is the separator located? Is it somewhere in the wall so they would need to open the wall?

It sounds like there could be a lot of air in the system that is causing flow issues and heat transfer. The discharge from the overflow when the system temperature was turned up could be a sign of thermal expansion or an expansion tank issue. It sounds like an air issue in the system a good air separator may be needed.

I live in an apartment 12th floor end unit. My heat goes off every 2nd day due to air blockage they say. They don't know what is wrong and are getting angry. What should I do?

In reply to I live in an apartment 12th by Eleanor Elliott

Eleanor, Air typically will rise to the highest point in the system and separates from the water easier as it is heated. Identifying how the air is getting into the system is important. There is always oxygen in water. I would recommend a good system air separator and possibly air vents at the high point in the system. If there is that much air in the system a good flush and fill followed up by air separation and vents should correct this.

If installing an air separator on a wall hung closed loop boiler system do I still need to bleed the lines to purge any air in them or will this eliminate that step? I'm in the process of replacing my 18yr old wall hung boiler with a new one. Figured I'd install a separator while I'm replacing the boiler. Was curious if using one eliminates having to bleed the lines. Appreciate the help

In reply to If installing an air by Jeff

Jeff, you should still purge your lines on initial fill and startup. The air separator will remove the entrained air over the following weeks as the system is up and running.

I noticed in a comment above that an air separator is not designed to work in a hydronic system where the hot water is heated by a hot water tank (conventional domestic electric hot water heater). Is that correct? If I have read this correctly, is there a product you can recommend that helps to get rid of microbubbles in my system which uses a hot water heater?

In reply to I noticed in a comment above by Paul Neufeld

Paul, air separators are designed to work in a closed loop hydronic system, and not a domestic water system. They are not made of low lead brass, and therefore cannot be installed on the domestic side. If you are having trouble with air trapped in your domestic system, you could install our Plumbvent at high points in your system, as it is the only low lead automatic air vent on the market.