We get this question often: "What is the pressure drop in my hydraulic separator?" It's a good question; after all we know that the circulator adds head energy and everything else in a hydronic system causes head energy losses. The answer to the question is: "It's negligible; you don't need to include it in your head loss calculations".

The reason you don't need to include it is from one connection to the other (for example, the secondary return inlet to secondary supply outlet) essentially all you have is the large open barrel of the separator which offers no resistance to flow. The barrel typically has nine times the cross sectional area than the inlet/outlet pipes. The velocity in the barrel is 1/9th of the velocity in the piping. In this low flow area, the dynamic pressure drops between all four ports is almost zero.

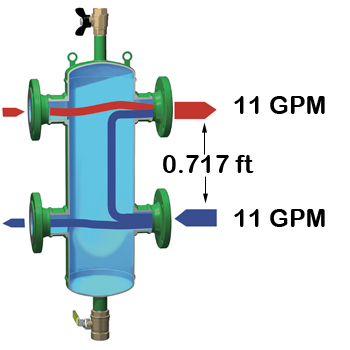

Let's calculate a head loss example. For the pressure drop between the secondary return inlet and secondary supply outlet, for a 1" sweat Caleffi 548096A separator, using the equation on page 17 of Caleffi idronics issue #16:

Assume we have 11 GPM (max flow rating) of 140˚F degree water. Referring to pages 17 and 18 in the idronics journal:

a = .047 (from Figure 4-2)

c = .0001278 (approximate value, for flow through the 3" barrel of the separator)

L = 0.717 (length between supply and return connections of the separator, ft.)

f = 11 GPM

So the head loss through the separator, in the secondary piping circuit, is approximately 0.0003 PSI or 0.0007 ft. of head. Negligible.

The example was a very small Hydro Separator. Here is a very large one from GOES in Houston Texas.

https://www.caleffi.com/sites/default/files/file/01249-17_nar1.pdf

The Hydraulics characteristics table is for 4FPS for the sep 4 549. I need the information in 10fps for 4" and 3".