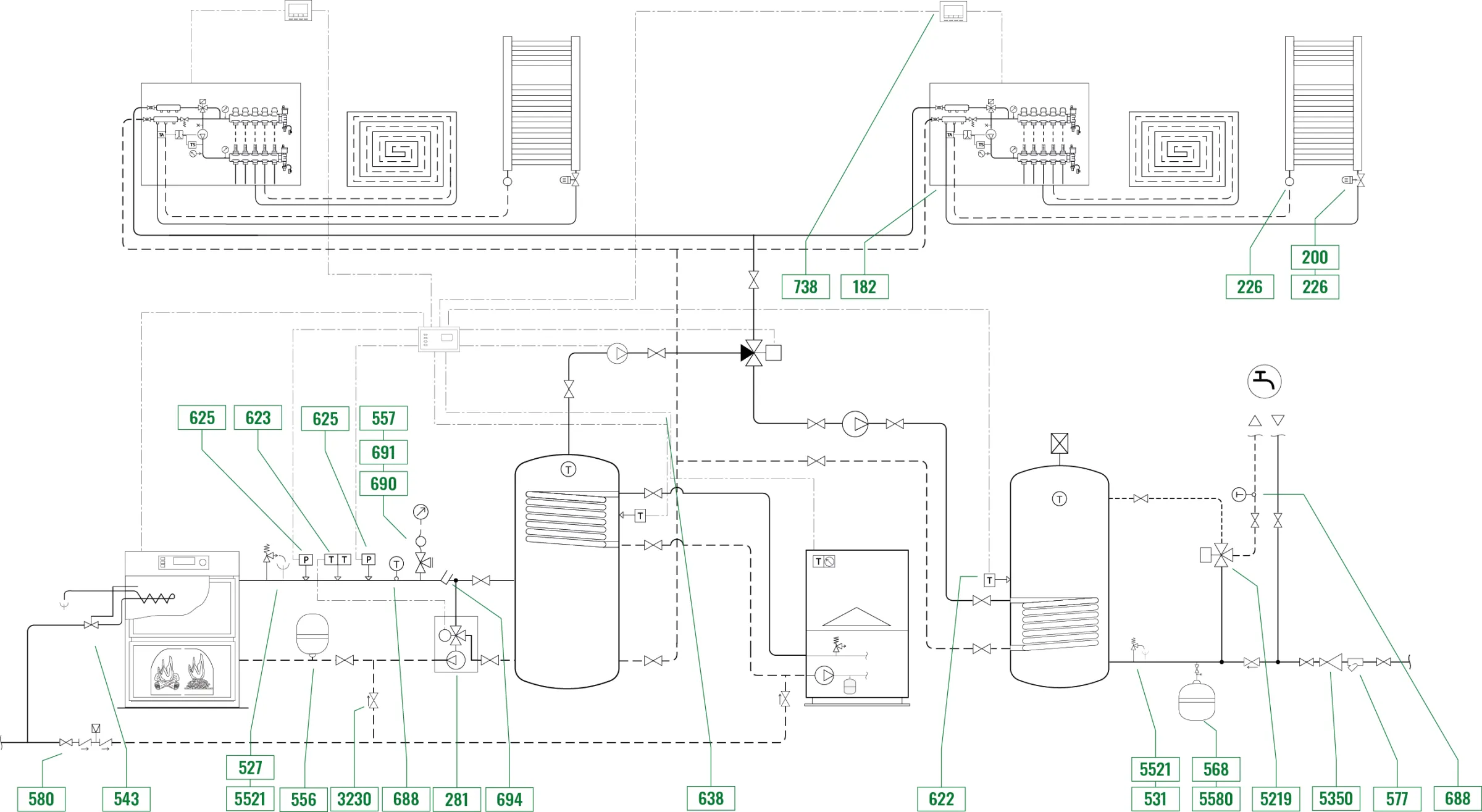

The system can be divided into 5 zones:

Biomass boiler zone

This consists of:

· Biomass boiler with automatic air supply

· Control, expansion, safety and heat discharge equipment

· Anti-condensation circulation unit with the following components: anti-condensation thermostatic sensor, circulation pump, natural circulation clapet valve, built-in ball valves and verification temperature gauges

Traditional fuel-fired boiler zone

This consists of:

· Condensing boiler with internal circulation pump

· Control, expansion and safety equipment.

Inertial tank zone with heating medium distribution

This consists of:

· Inertial tank with single top coil

· Three-way diverter valve, for priority domestic hot water production

· High efficiency circulation pump

The storage tank with top heat exchanger can be used to manage the two heat sources easily and satisfy two objectives: to produce domestic hot water with storage and to heat the room.

Heating zone

This consists of:

· Dual-temperature set point regulating unit

· Radiant panel system and towel warmer

· Room chrono-thermostat

The hot medium is used both to produce domestic hot water and to supply the radiators.

Domestic hot water production and distribution zone

Domestic hot water production takes place in the relevant storage tank and takes priority over heating.

The anticipated distribution system is without recirculation and is equipped with a thermostatic mixing valve with strainers and check valves built into in the hot and cold water inlet connections.

System management

The thermostat positioned on the “technical” water storage tank or the room chrono-thermostat is connected to the biomass boiler controller.

If the thermal load is insufficient, the controller manages gas boiler ignition. The thermostat on the DHW storage manages the priority diverter valve by inhibiting the flow to the room heating section. Once domestic hot water production demand has been satisfied, the diverter valve is routed towards the heating system.

The secondary circulator starts up with the consent of the room chrono-thermostat or the diverter valve microswitch.

The regulating unit is used to control the temperature and the flow rate to the radiant panel system and to supply the towel warmers directly from the high temperature circuit.

Note:

The control, expansion and safety equipment must be of appropriate size to reflect the heating capacity and specific characteristics of the system, in accordance with applicable laws and regulations.

If necessary, or if required by current legislation relating to water hardness, the heating system water must be suitably treated.