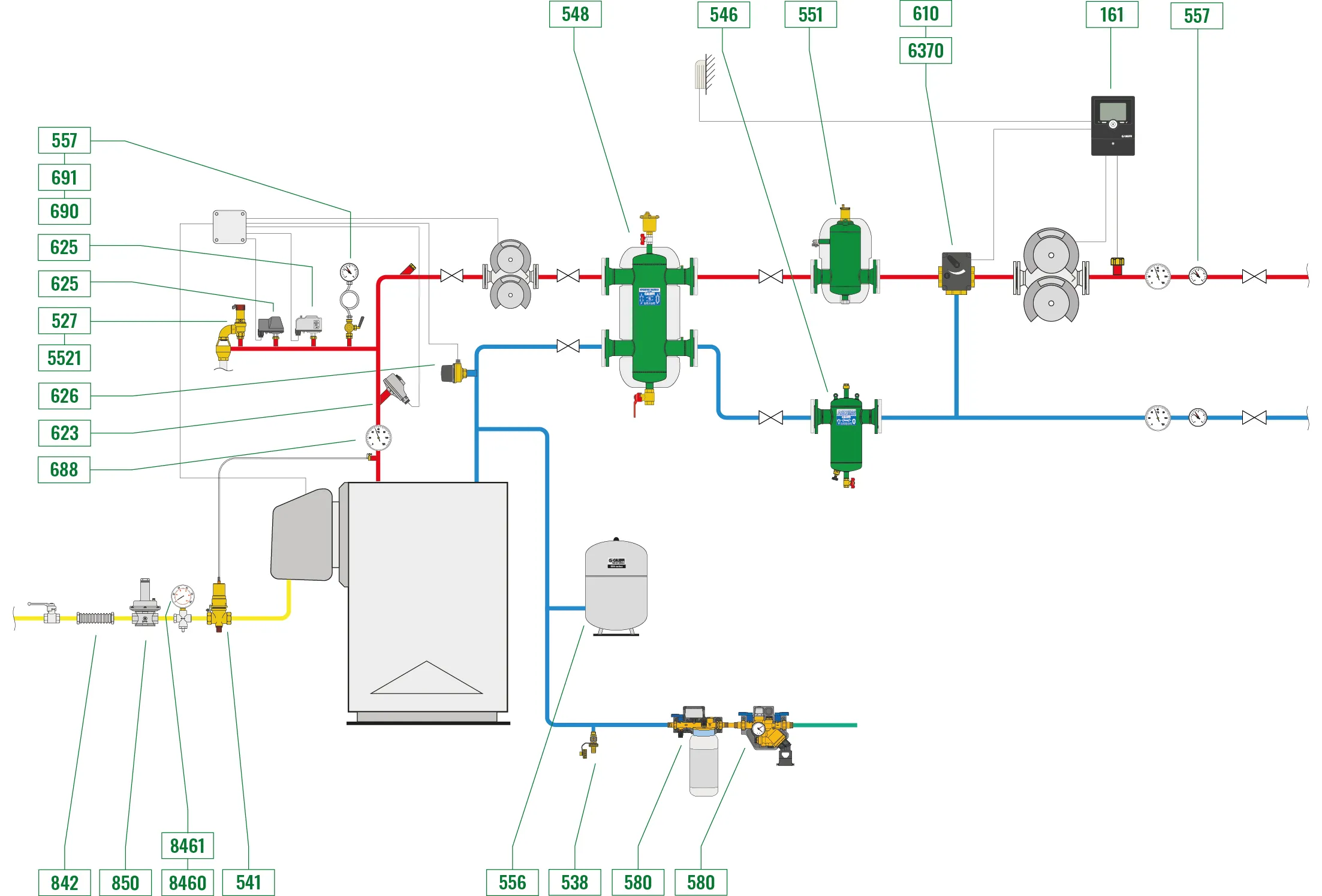

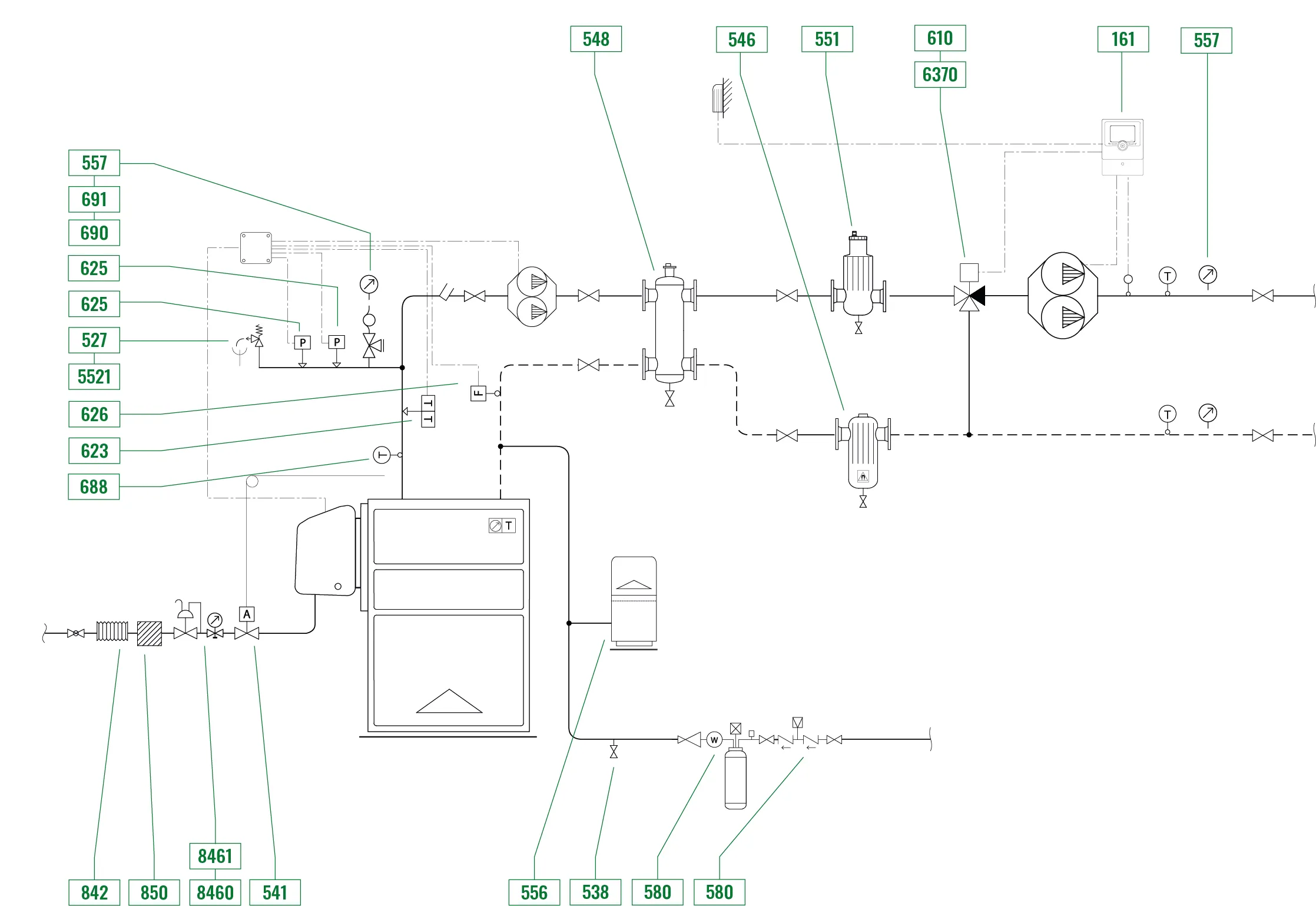

The central heating system essentially consists of:

- Boiler

- Hydraulic separator

- High efficiency tandem circulation pumps

- Three-way regulating valve with climatic controller

- Control, expansion and safety equipment

- System charging unit with pressure reducing valve and backflow preventer

- Equipment for deaerating the system water and removing suspended contaminants

This layout is generally used for systems with a constant flow rate and a thermal medium temperature which varies depending on the outside temperature.

The configuration with boiler and hydraulic separator makes it possible to run the system with the minimum possible flow rates in circulation (which translates into savings in terms of pump management) and with low return temperatures (and therefore greater efficiency of condensing boilers).

The deaerator serves to eliminate air pockets and micro-bubbles from the system water, thereby limiting corrosion and noise.

The dirt separator with magnet intercepts and removes dirt particles normally suspended in the water of heating systems. In particular, the magnet is designed to intercept particles of magnetite, thus preventing them from collecting (and causing serious damage as a result) on the magnetic rotors of the new high-efficiency pumps. It should be installed on the secondary circuit to capture the sludge closest to the system, utilising the reduced partial flow rate in circulation.

The temperature of the secondary circuit is regulated by a mixing valve, so as to offer greater flexibility and energy efficiency.

If necessary, or if required by current legislation relating to water hardness, the heating system water must be suitably treated.

Note:

The control, expansion and safety equipment must be of appropriate size to reflect the heating capacity and specific characteristics of the system, in accordance with applicable laws and regulations.