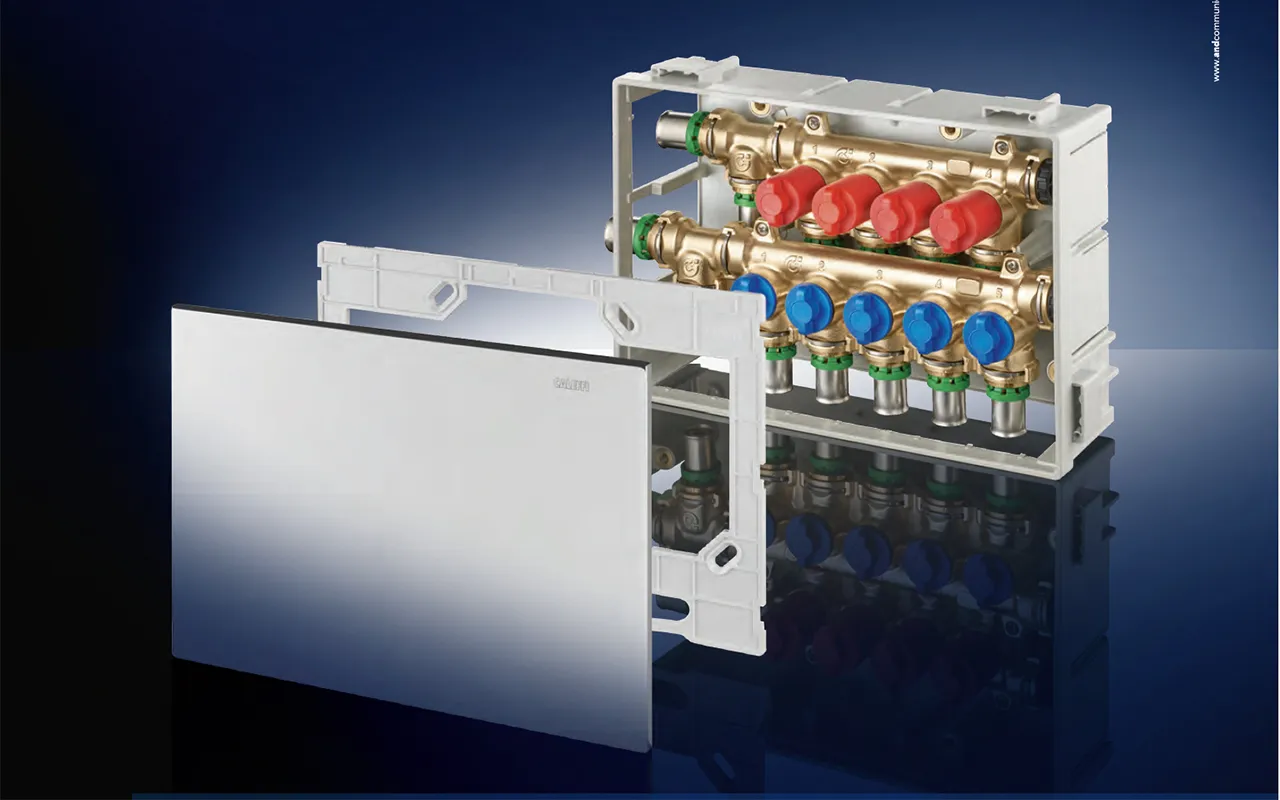

New distribution manifolds for effective domestic water distribution

The new Caleffi 359 series manifolds are suitable for creating flexible domestic water distribution systems that comply with the safety standards while greatly simplifying maintenance operations. Great focus has also been placed on key aspects such as compact installation, finish aesthetics of the boxes and quick connections for recirculation pipes on the DHW and DCW sides.

Product advantages of Caleffi distribution manifold for domestic water systems

- Calibrated constant pressure and flow rate

- Simplified maintenance with easy access to the shut-off valves

- Multiple box finishes to adapt perfectly to any needs

- Simplified maintenance with easy access to the shut-off valves

- Designed for quick connection of recirculation pipes on both the DHW and DCW sides

Why should you install a distribution manifold?

An effective domestic water distribution system must offer the benefits of both comfort and economic savings so that the end user can avoid wasting a precious commodity such as potable water. Moreover, to prevent the proliferation of hazardous bacteria such as legionella, the Higher Health Institute has given precise instructions on how to make the system, emphasizing the importance of preventing water stagnation in the pipes and providing adequate recirculation systems for adduction of DHW (domestic hot water) and DCW (domestic cold water).

All these aspects must necessarily be considered when designing and making a domestic water distribution system in order to guarantee the best result for the end user.

To ensure that the end user does not have to put up with inadequate or excessive flow rates, the distribution manifold for the “domestic utilities” – i.e. the terminals that supply DHW or DCW in bathrooms and kitchens, such as wash basins, bidets, showers, etc. – must be able to distribute the correct amount of water to each individual tap without significantly affecting the distribution pressure at the various drawing points.

The manifold also provides a convenient point to access the system for simple routine checks or maintenance work in the event of a fault.

Which installations is the 359 distribution manifold meant for?

Because of its wide range, the new 359 series domestic distribution manifolds can adapt to any kind of installation and meet these requirements perfectly. In fact, it is possible to choose between the version complete with shut-off valves for each individual utility, that with main shut-off valves, or just the shut-off valve unit without the distribution part.

- The 359 series manifold with shut-off valves for each individual utility has a box with push-to-open technology for a finish that is flush to the wall. This ensures that the manifold integrates perfectly into the room in which it is installed, minimising its aesthetic impact. Alternatively, it is possible to opt for cover plates with a white or steel finish. The shut-off valves have replaceable cartridges with a double sealing gasket system designed to offer high operating reliability. Combined with the materials used, this system reduces the operating torque and makes it very unlikely that limescale can seize the shut-off mechanism. The distribution manifold can be combined with screw-on fittings or press fittings thanks to the fixing clip system, which is ideal when the installer must work in awkward or cramped spaces. The available accessories include a Tee connection kit to be placed at the manifold inlet. This system makes it possible to branch off the recirculation pipe directly inside the inspection box in a simple, fast and compact manner, not just for the DHW, but also for the DCW to meet the latest requirements.

- The 359 series manifold with main shut-off valves can isolate the entire distribution box from the rest of the system. With this configuration, there is no need to access the whole manifold to carry out maintenance. The box is finished with a plate that contains just the two control knobs, with push to open technology to ensure that they remain flush with the wall when not in use. The shut-off valves are made of specific materials to ensure low operating torques, and can be replaced directly by removing just the closing plate, without the need to access inside the box. The branches for connecting the recirculation pipes are built directly into the manifold body, upstream from the shut-off valves. This avoids the need to make hydraulic connections in places that are not easily accessible for maintenance. Since it is not possible to access inside the box with this version, press fittings must be used to connect the main and branch pipes.

- Version with main shut-off valves only. When it is necessary to guarantee flushing up to the various utilities in order to prevent stagnation of the medium, a ring configuration or through configuration with flushing point can be used. A main shut-off valve unit is sufficient for these two types of installation. With this configuration, the unit is fully adjustable and designed for connecting both the recirculation pipes on the main adduction side, and the branches for the ring connection inside the utility. As for the manifold with main shut-off valves, this component has a closing plate with control knobs, making it completely invisible within the room.