For on/off control, it is common practice to select a valve with connections that are the same size as the piping. This approach is sound as long as two things are verified: the close-off pressure of the valve assembly and the head loss added to the system (pressure drop across the valve).

A given size valve body can have multiple Cv ratings. Start by selecting the largest Cv available in the valve body that matches the piping size. This offers maximum flow capacity and minimum pressure drop (head loss added to the system), which are both good things. However, make sure the close-off rating of that valve assembly is greater than the maximum differential pressure that could ever exist across that valve at its location in the piping. If the close-off rating is sufficient, the valve assembly is the right choice. If the close-off pressure rating of the assembly is not sufficient, select a model with a smaller Cv. A smaller Cv will have a higher close-off rating, however, it will also decrease the flow capacity of the valve and add head loss to the system.

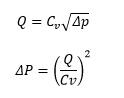

Verify that the flow capacity is sufficient for the load and verify the added head loss is still acceptable. Here are the equations to use:

Q = flow (GPM)

Cv = valve Cv

Δp = actual pressure drop across the valve (PSID)