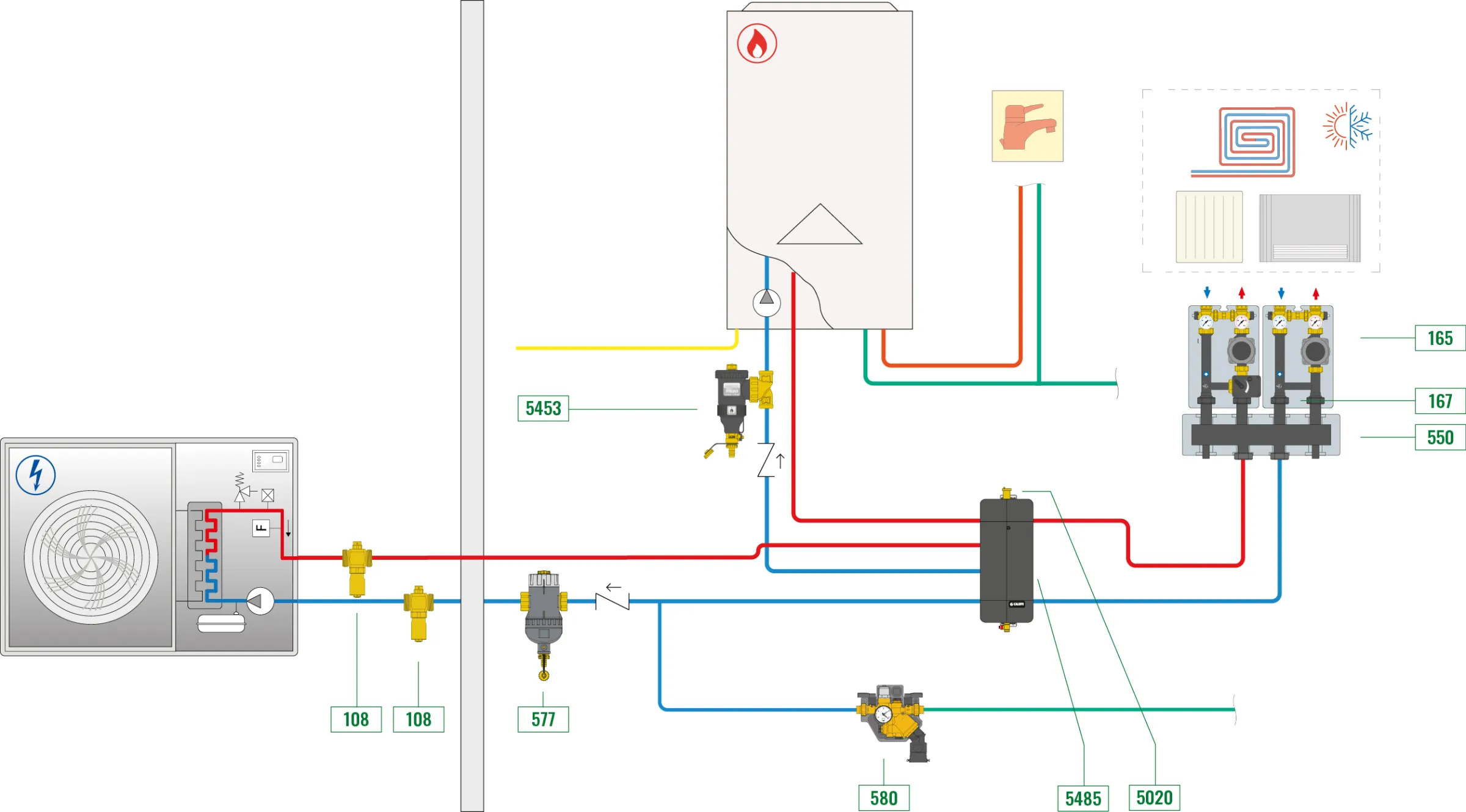

The system consists of a primary circuit which includes:

- Condensing boiler

- Monobloc heat pump

- Inertial storage with hydraulic separator function

- Antifreeze devices to protect the monobloc heat pump

- Water treatment devices (dirt separator) for the protection of generators and, more generally, all system components

- System charging unit with pressure reducing valve and backflow preventer

The boiler and heat pump are connected in parallel to a thermal storage tank with 4 connections on the primary circuit side. The two generators can work alternately or at the same time; the storage tank also functions as a hydraulic separator and makes the two circuits independent.

The secondary circuit consists of:

- Central unit manifold

- Direct booster unit

- Motorised regulating and booster unit

This solution is generally used in the following cases:

- Renovation: adding a heat pump to an existing system with wall-mounted boiler

- New systems using non-integrated generators

The layout is optimised for a system which runs in both heating and cooling phases.

Instantaneous hot water production simplifies system configuration but should be assessed according to specific needs.

There are multiple advantages to this solution: no space is required for a domestic hot water storage tank if you accept the resulting limitation on the number of users. Conditions in which Legionella bacteria develop are not created: the water is only heated as it is used and this dispenses with the need for thermal disinfection of the distribution network.

In winter, the heating function can be carried out by the heat pump while the boiler is producing domestic hot water.

In summer, the heat pump only produces chilled water and never has to reverse the cooling cycle to produce DHW.

Note:

The control, expansion and safety equipment must be of appropriate size to reflect the heating capacity and specific characteristics of the system, in accordance with applicable laws and regulations.