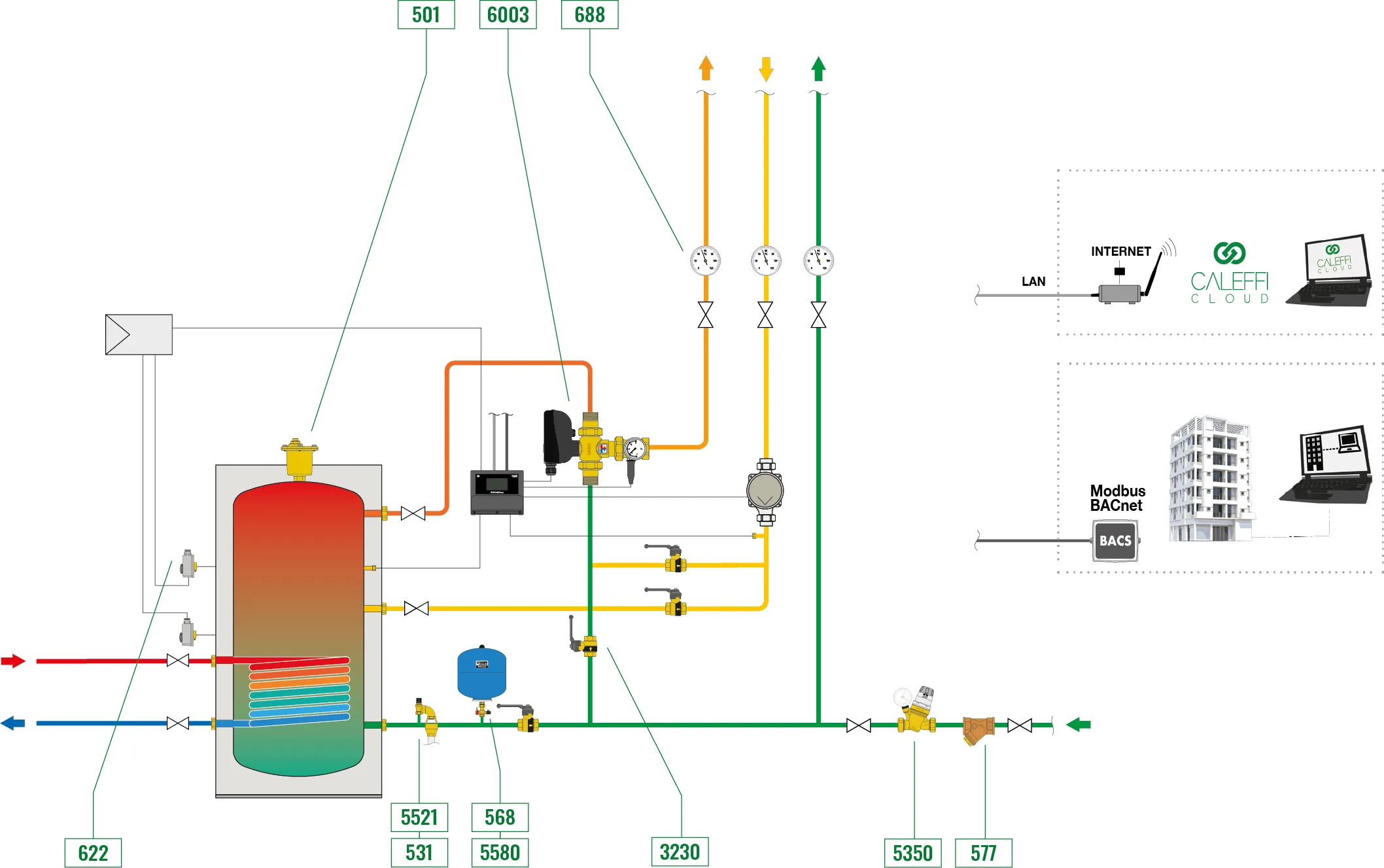

The scheme represents a centralized plant for the production and distribution of domestic hot water (DHW), intended to serve multiple units or environments within complex buildings such as collective residences, accommodation facilities, hospitals or large commercial buildings. In this type of configuration, the production of the DHW is entrusted to one or more storage kettles, possibly arranged in parallel to meet high demands or to facilitate scheduled maintenance interventions without interruption of service.

The storage temperature is regulated by means of a mechanical thermostat or, alternatively, with an electronic probe, which allows a modulated management of the pump or generator according to the actual temperature. The temperature of the distributed water is instead regulated by a centralized electronic mixer, which ensures a stable and controlled delivery, even during programmed cycles of thermal disinfection.

The DHW distribution network is branched and feeds the individual users with a system of locally positioned anti-burn mixers, to protect the end user. A carefully sized and balanced recirculation system is essential to maintain the temperature even in the most remote stretches and reduce thermal losses.

From a design point of view, the system requires careful design, in particular with regard to recirculation sizing, hydraulic balancing, adjustment of loads and selection of control components.

The operating performance is high thanks to the precise temperature control, guaranteed by the electronic mixer, which in the most advanced models monitors the delivery, return and also those inside the kettle. This capability allows to identify in real time any failures of the disinfection cycles due to insufficient temperatures in the accumulation.

The new electronic mixers also include "failsafe" safety systems, which return the valve to the closed position in the event of an interruption of the power supply, or activate emergency valves in the presence of dangerous conditions inside the system. From the interface point of view, traditional displays are replaced by touch screen panels, which facilitate configuration by the installer.

The management of the recirculation pump is carried out directly by the electronic controller, improving the efficiency and reactivity of the system.

The most innovative feature is the remote connectivity, enabled via ModBus or BACnet protocols, which allows the connection to the Caleffi Cloud platform. Through a dedicated dashboard, you can view graphs, detailed tables, manage controller settings and download system reports, which are essential to demonstrate compliance with the most up-to-date regulations and guidelines. Remote configuration also simplifies predictive maintenance, while always maintaining the supervision of an on-site technician, as required by safety requirements.

From a hygienic-sanitary point of view, the system allows effective monitoring of Legionella throughout the network, thanks to the ability to program and document each disinfection cycle in a traceable way.