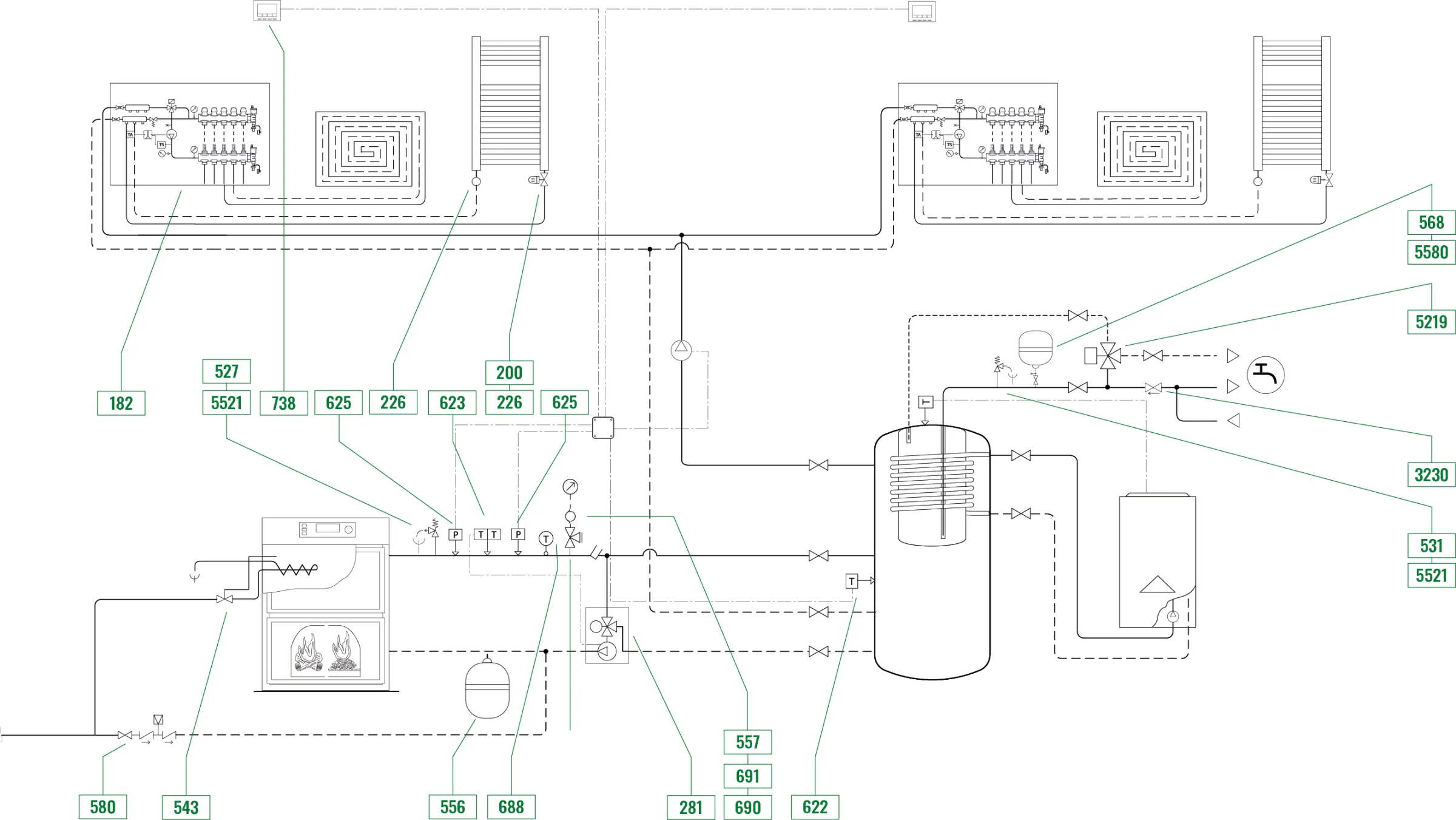

The system can be divided into 4 zones:

Biomass boiler zone

This zone is essentially composed of:

· Biomass boiler with automatic air supply

· Control, expansion, safety and heat discharge equipment

· An anti-condensation circulation unit with the following components: anti-condensation thermostatic sensor, circulation pump, natural circulation clapet valve, built-in ball valves and verification temperature gauges

The anti-condensation circulation unit pump is activated by the contact thermostat when the temperature of the water exceeds the minimum value requested by the boiler manufacturer.

Traditional fuel-fired boiler zone

This essentially consists of a floor-standing boiler, internally fitted with all regulation and safety components.

Inertial tank zone with heating medium distribution

This zone is essentially composed of:

· “Tank-in-tank” combined water storage

· Charging unit

· Heat emitters: radiant panels and radiators

Distribution of the heating medium is achieved via regulating units for panels, by-pass type, and primary medium distribution kits for radiators. Correct by-pass valve adjustment is essential in this configuration.

Domestic hot water production and distribution zone

Domestic hot water production is obtained in the tank inside the inertial storage.

The anticipated distribution system is without recirculation and is equipped with a thermostatic mixing valve with strainers and check valves built into in the hot and cold water inlet connections.

Note:

The control, expansion and safety equipment must be of appropriate size to reflect the heating capacity and specific characteristics of the system, in accordance with applicable laws and regulations.

If necessary, or if required by current legislation relating to water hardness, the heating system water must be suitably treated.