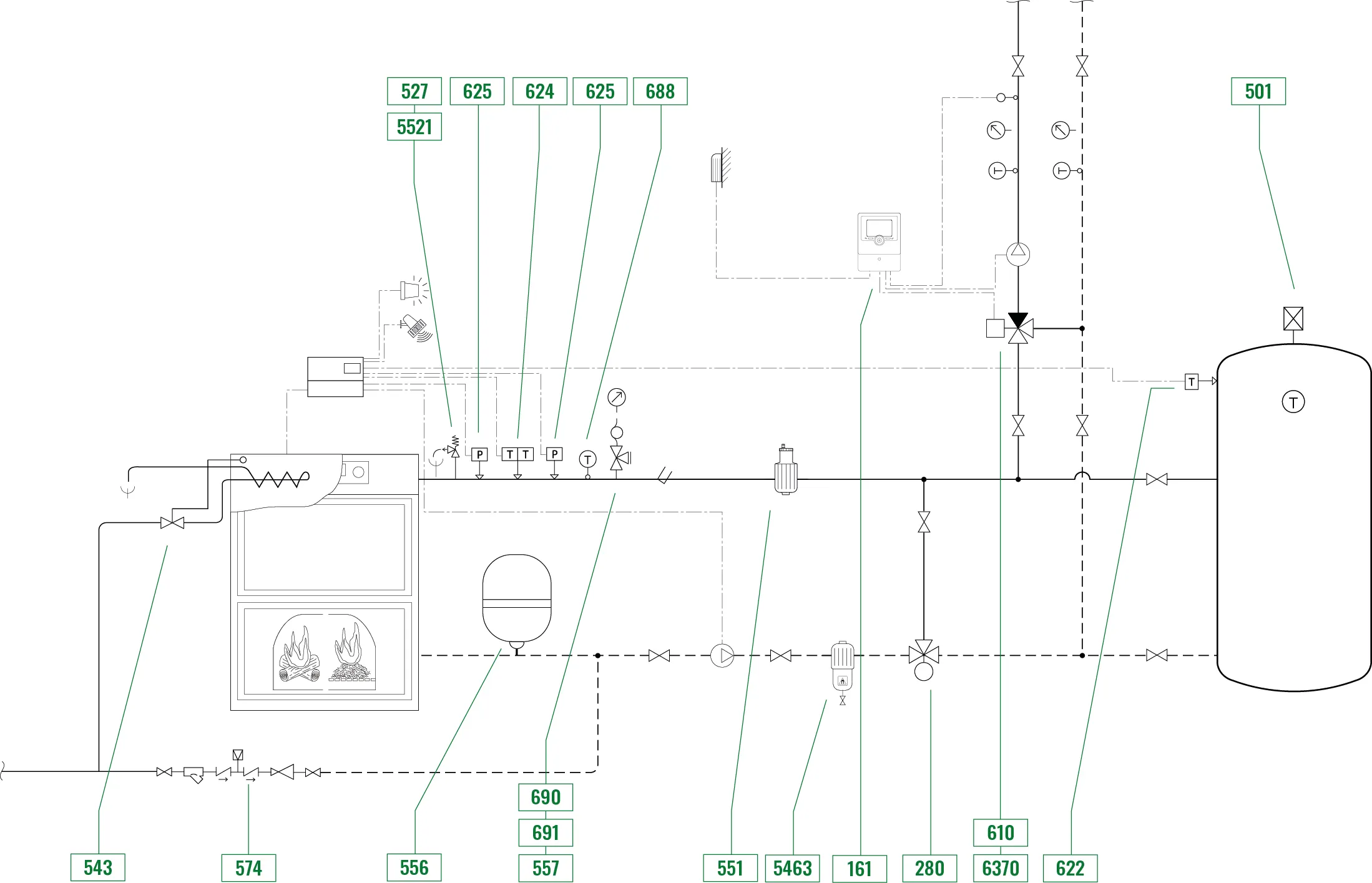

The central heating system can be divided into 2 zones:

Biomass boiler zone

This zone is essentially composed of:

- 1 boiler with automatic air supply

- 1 high efficiency tandem circulation pump

- 1 three-way thermostatic radiator valve to prevent water with a temperature value that is too low from returning to the boiler

- Control, expansion and safety equipment

- 1 charging unit with pressure reducing valve and backflow preventer

- Water treatment devices (dirt separator and deaerator) for the protection of generators and, more generally, all closed system components

Inertial tank zone with heating medium distribution

This zone is essentially composed of:

- 1 inertial tank

- 1 high efficiency tandem circulation pump

- 1 three-way regulating valve with climatic controller

- Control and shut-off devices

Three typical operating situations may occur:

- Biomass boiler on and distribution circulator off: the heat produced by the wood-fired boiler brings the water storage tank to temperature;

- biomass boiler on and distribution circulator on: the heat produced by the wood-fired boiler is conveyed to the distribution system;

- Biomass boiler off and distribution circulator on: the distribution system utilises the heat stored previously in the water storage tank.

This configuration can also be applied in medium-large systems; in this case the devices for closed vessel systems should not be installed.

This solution is generally used in systems with heat interface units or with local DHW production, i.e. with zone outlets able to provide both heating and domestic hot water production, or in systems with local DHW production.

The water temperature at the outlet to the radiators can be regulated, with outside compensated temperature curve and minimum temperature limit of between 60 and 65 °C.

Note:

The control, expansion and safety equipment must be of appropriate size to reflect the heating capacity and specific characteristics of the system, in accordance with laws and regulations.