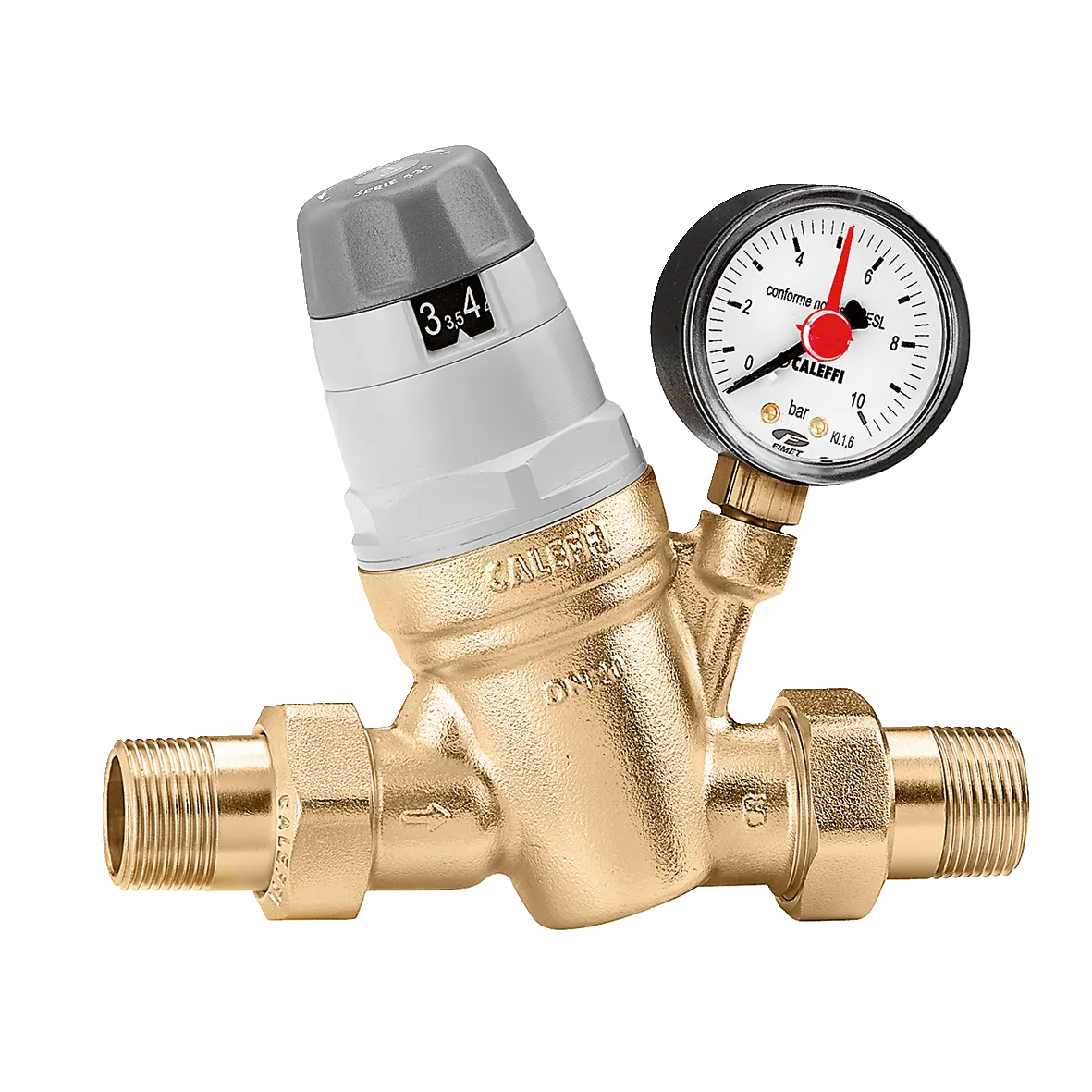

Pressure reducing valve with self-contained replaceable cartridge.

Product Description

Pressure reducing valve with self-contained replaceable cartridge.

Male union connections.

With pressure regulating scale for manual pressure adjustment.

Certified to EN 1567.

PATENT

Technical data

Note

535074, 535075 (1 1/4" M) complete with 1" cartridge. Not DVGW certified.

Certifications

Download

Drawings and specifications

| Part number | Connection | Note | |

|---|---|---|---|

| 535040 | R 1/2" (EN 10226-1) M union |

With 1/4” F pressure gauge connection | |

|

2D drawings

3D models

Tender text

CALEFFI, 535040.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1/2" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

78d6a4e6-4794-4da3-b4f3-416caadc9f39

|

|||

| 535050 | R 3/4" (EN 10226-1) M union |

With 1/4” F pressure gauge connection | |

|

2D drawings

3D models

Tender text

CALEFFI, 535050.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 3/4" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

dca99ffb-74ee-409f-b258-08cacb95753f

|

|||

| 535060 | R 1" (EN 10226-1) M union |

With 1/4” F pressure gauge connection | |

|

2D drawings

3D models

Tender text

CALEFFI, 535060.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

3dce134e-770b-4a72-a018-92377f19e061

|

|||

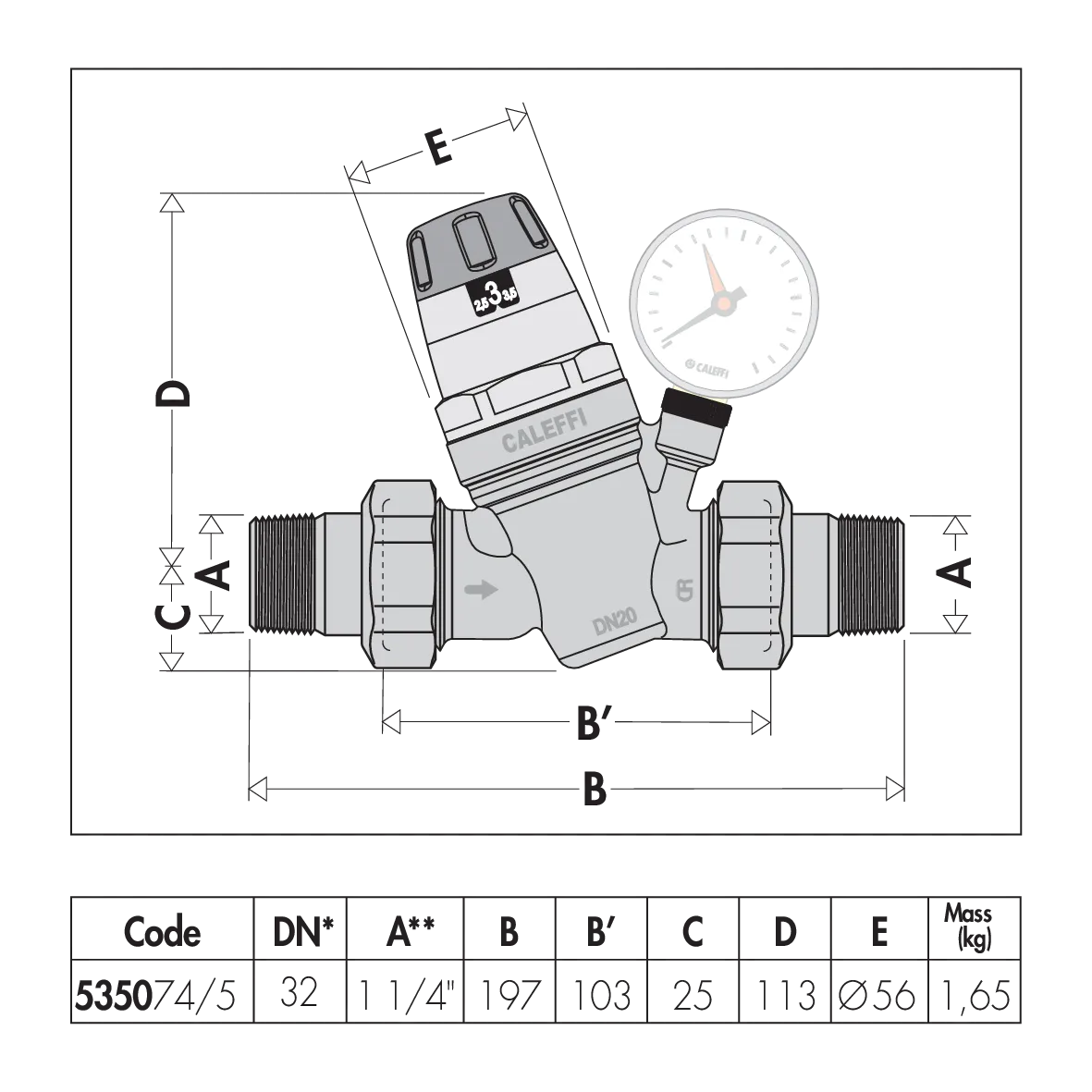

| 535074 | R 1 1/4" (EN 10226-1) M union |

With 1/4” F pressure gauge connection | |

|

3D models

Tender text

CALEFFI, 535074.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1 1/4" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

c371c488-9e71-4dc8-8d56-8e4b9ca8a80f

|

|||

| 535070 | R 1 1/4" (EN 10226-1) M union |

With 1/4” F pressure gauge connection | |

|

3D models

Tender text

CALEFFI, 535070.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1 1/4" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

5df70493-87bf-47f6-b7ce-f4b2d78d752a

|

|||

| 535080 | R 1 1/2" (EN 10226-1) M union |

With 1/4” F pressure gauge connection | |

|

3D models

Tender text

CALEFFI, 535080.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1 1/2" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

ecbdf742-6280-4ed5-84b7-ca40e5af591a

|

|||

| 535090 | R 2" (EN 10226-1) M union |

With 1/4” F pressure gauge connection | |

|

3D models

Tender text

CALEFFI, 535090.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 2" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

7a504cc8-6e3f-452f-8953-522e70ccbdb7

|

|||

| 535041 | R 1/2" (EN 10226-1) M union |

With pressure gauge 0–10 bar | |

|

2D drawings

3D models

Tender text

CALEFFI, 535041.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1/2" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

18ccbde8-08d6-4f43-8b83-fac6b9fb13ef

|

|||

| 535051 | R 3/4" (EN 10226-1) M union |

With pressure gauge 0–10 bar | |

|

2D drawings

3D models

Tender text

CALEFFI, 535051.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 3/4" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

238e306a-ab65-4c42-8299-1f022357227a

|

|||

| 535061 | R 1" (EN 10226-1) M union |

With pressure gauge 0–10 bar | |

|

3D models

Tender text

CALEFFI, 535061.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

ba3862bd-1af2-47ea-aabc-9ca37eab61c4

|

|||

| 535075 | R 1 1/4" (EN 10226-1) M union |

With pressure gauge 0–10 bar | |

|

3D models

Tender text

CALEFFI, 535075.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1 1/4" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

9aec7c31-b741-4018-88c1-d1ba626092c0

|

|||

| 535071 | R 1 1/4" (EN 10226-1) M union |

With pressure gauge 0–10 bar | |

|

3D models

Tender text

CALEFFI, 535071.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1 1/4" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

98c7d2d1-915e-4a83-b364-ae47df7ff80e

|

|||

| 535081 | R 1 1/2" (EN 10226-1) M union |

With pressure gauge 0–10 bar | |

|

3D models

Tender text

CALEFFI, 535081.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 1 1/2" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

e64076c6-8bdc-4855-b28e-fe7ff2719519

|

|||

| 535091 | R 2" (EN 10226-1) M union |

With pressure gauge 0–10 bar | |

|

3D models

Tender text

CALEFFI, 535091.

Pressure reducing valve with self-contained replaceable cartridge. Male union connections.

With pressure regulating scale for manual pressure adjustment. Certified to EN 1567.

Connection: R 2" (EN 10226-1) M, union. Maximum upstream pressure: 25 bar. Medium temperature range: 2–40 °C. Adjustment pressure range: 1–6 bar. Material: dezincification resistant brass DR.

SCIP code

1b43314e-1bbd-45f9-bfca-0f2fc1908821

|

|||

Faq - Frequent questions

Just remove the impurities. In the case of the 535 series pressure regulators (in the drawings), this procedure is extremely simple because the regulator insert is one element that can be unscrewed with a wrench. After cleaning, the insert must be installed. There is no need to recalibrate, the pressure will be maintained according to the setting on the knob. A similar procedure can be performed for the 533 series regulators, but these require the pressure to be re-set. The second case occurs in installations where the water pressure regulator is installed in the supply of the domestic hot water tank. Unfortunately, such installation is often performed when there is no expansion vessel in the cold utility water installation. Omission of such an important element results in periodic activation of the safety valve. This happens due to the increase in pressure in the tank during water heating.

The water pressure regulator stabilizes the pressure to the set value and it remains unchanged regardless of pressure fluctuations in the water supply network. The reducer, on the other hand, reduces the pressure by a certain amount, which means that when the pressure on the water supply side changes, the pressure at the outlet of the reducer will also change.

1. Contaminants have got into the sealing area of the regulator seat, which does not close properly and causes a slight leak, the pressure tends to equalize on both sides of the regulator. The situation occurs, of course, without flow, with closed draw-off points, i.e. when the regulator should be closed. 2. The pressure gauge shows the pressure of water heated in the domestic hot water tank when the regulator is installed upstream of the tank. The heated water, under the influence of thermal expansion, flows back towards the pressure regulator and the high pressure has no outlet.

In such a case, we are most likely dealing with the phenomenon of cavitation. This phenomenon occurs when we reduce the pressure from high to quite low, then the water flow speed increases rapidly between the regulator's plug and its seat, which causes the pressure to drop to the so-called evaporation pressure. Air microbubbles are then produced. When the pressure begins to increase slightly again, the bubbles rapidly implode, which in turn produces a shock wave, damaging the regulator walls, seat, seals and causing the above-mentioned noise.