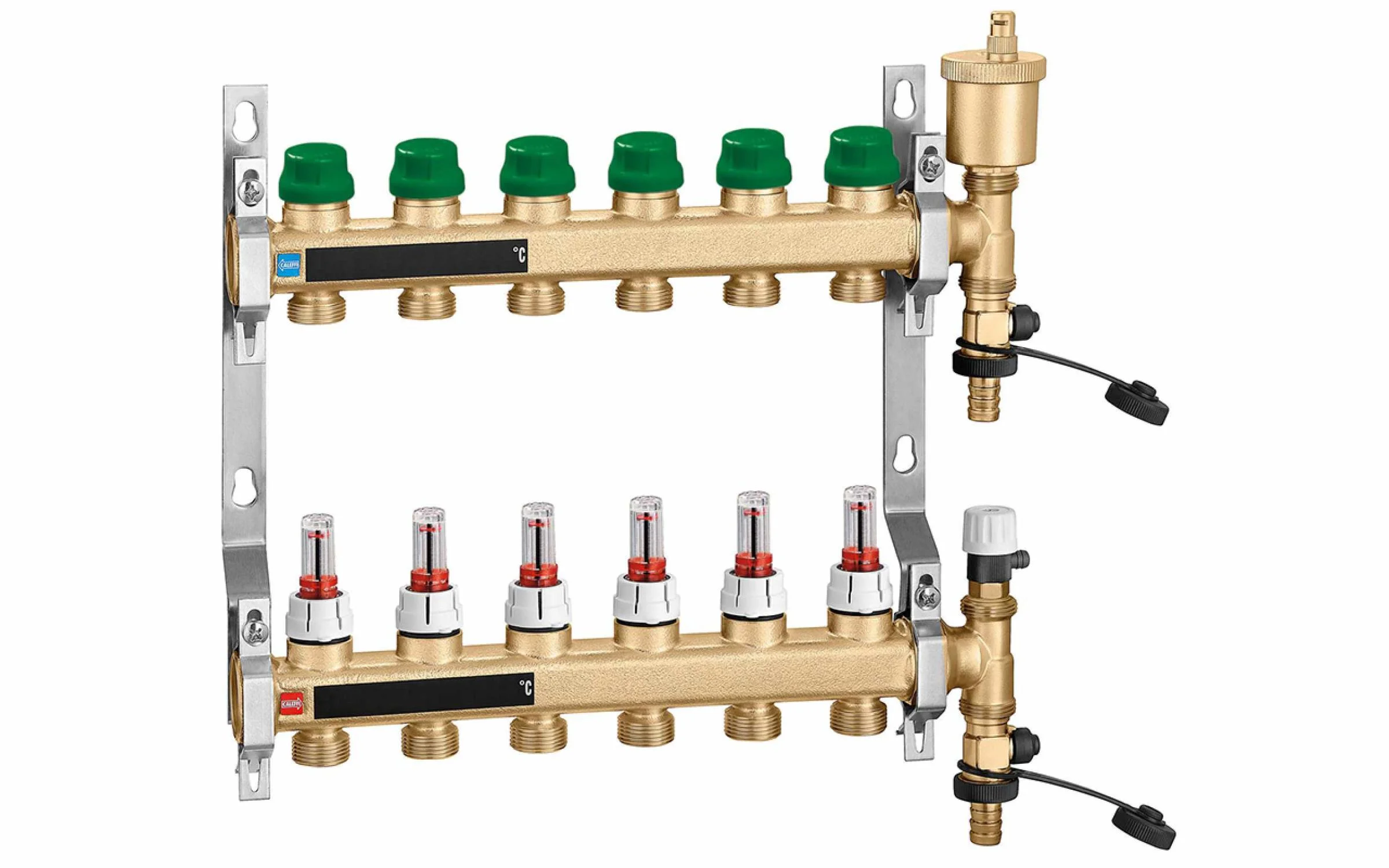

DYNAMICAL® manifold

Supplying the right flow of water to all terminals is essential to maximise the output of climate control systems, both in terms of thermal comfort for the user and for energy and cost savings.

Balancing the system may be easy when the system is running at full capacity, but is much more complicated when zone modulation starts, i.e. when some terminals start to close because their room temperature setpoint has been reached.

Modern technology has seen a change from fixed to variable flow systems, where heat control affects the amount of fluid flowing through the individual zones, reducing it to the minimum required to heat the room.

In static balancing systems, this variation affects the parts of the system which are still active, so that they are supplied with much more vector fluid than they really require, thus creating new imbalances in the distribution of heat and flow which compromise the efficiency of the entire climate control system.

It should also be borne in mind that the larger the installation, the more complicated the situation is bound to be.

So, how can we ensure properly balanced control in all operation modes? The simplest solution is to use dynamic devices which automatically respond to variations in the main distribution section, thus ensuring constant operating conditions for the components of the section they control.

Differential pressure regulators are valves which autonomously keep the ΔP between two points of the circuit constant; this means that the flow pre-regulation devices always receive the same intake head and hence are able to keep the flow to the terminal at the target value.

However, it is not always easy to find enough space to install differential pressure regulators, especially in underfloor heating systems.

The DYNAMICAL® manifold for underfloor heating systems is specially designed to solve such balancing problems in this type of circuit.

The manifold is equipped with all the components you might need in a distribution system for underfloor heating installations, including flow meters which display the flow of each circuit, air venting valves, charging and draining valves and thermometers displaying the operating temperature, and also has a device for balancing and controlling the individual circuits.

The dynamic valve heads on the return manifold are made of a motorisable shut-off system, a flow pre-regulation device and a differential pressure regulator built into the component.

The regulator keeps the head acting both on the flow pre-regulation device and on the shut-off valve constant, thus enabling them to work in ideal conditions and ensuring control of the supply to the circuit.

Using this system greatly simplifies initial balancing.

Thanks to the flow pre-regulation system, you can set the desired value, from 25 to 150 l/h, directly at the valve head with the included wrench, so as to limit the maximum amount of fluid that can flow through the circuit.

The action of the differential pressure regulator keeps this pre-regulation constant even when the peripheral loops and other parts of the circuit are closed, by absorbing the increased head which is generated in the new operating conditions.

This technology is a perfect match for centralised underfloor heating systems, where high flow rates and strong, continual variations in the system make it difficult to control and distribute the vector fluid, and it is not always easy to install dynamic balancing devices for each zone.

The special technology of the DYNAMICAL® manifold makes the product quite compact (it can be installed in an 8 mm housing), so that it can be used in any installation, even where there is little to no space available.