Install the Caleffi backflow preventer with multi-function geometry

WHAT IS A BACKFLOW PREVENTER?

The backflow preventer is a device used in systems that pose a risk of polluting the potable main water system: it prevents contaminated water from returning from users' systems due to an accidental pressure reduction in the distribution system. It protects the main water system from downstream pressure, back siphoning and backflow. The version for special applications is used for taps on stands, at trade fairs, events, construction sites, garden irrigation, washing systems, pressure washing, car washes, and connection of hoses using the hose connection supplied as standard.

IMPORTANT CONSIDERATIONS ON INSTALLING A MULTI-FUNCTION GEOMETRY BACKFLOW PREVENTER?

The 580 backflow preventer with multi-function geometry must be installed in an accessible area, where there is no risk of accidental flooding or frost.

If there is a risk of frost, especially for the backflow preventer version for special applications, it is recommended to remove the device during the coldest hours.

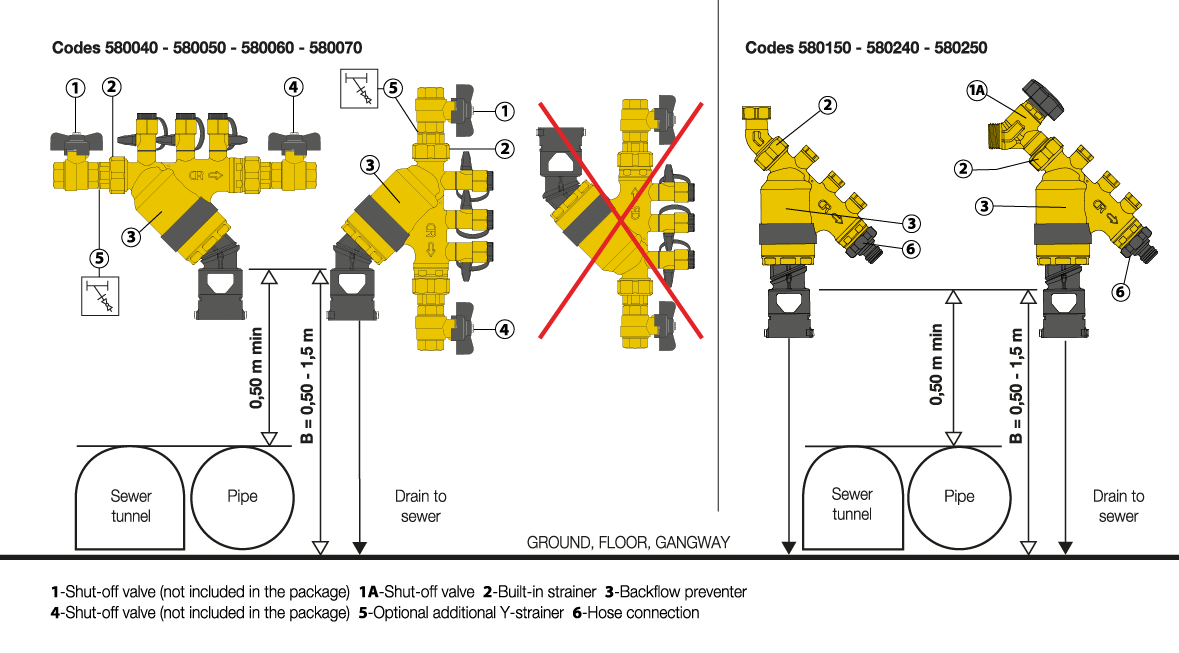

- The discharge tundish must be turned downwards and connected to the pipe leading to the sewer.

- For the protection of the public mains the backflow preventer must be installed after the water meter, whereas in order to protect the tap water outlets of the domestic internal network it should be installed at the limit of the areas where there may be contamination due to backflow.

- The in-line backflow preventer, codes 5800.0, must be installed with one shut-off valve upstream and one downstream (not supplied in the package).

- According to the indications of regulation EN 1717, the backflow preventer is equipped with an inspectable strainer, located in the upstream connection of the body and easily accessible for maintenance, and an adjustable discharge tundish.

- The appliance should be installed horizontally, in accordance with the flow direction indicated by the arrow on the valve body.

- It can also be installed on a vertical pipe with downward flow (from top to bottom), respecting the direction of flow indicated by the arrow on the valve body. In the case of particularly dirty mediums, consider installing an additional inspectable strainer upstream.

The pictures below show: The various possible installation positions of the Caleffi 580 backflow preventer with multi-function geometry.

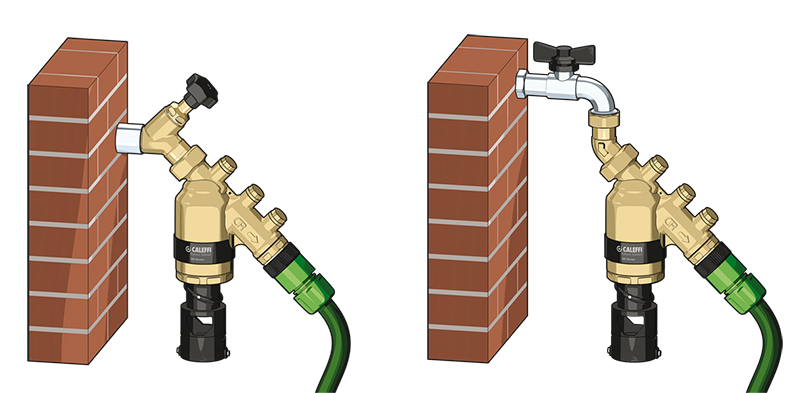

HOW CAN THE BACKFLOW PREVENTER BE INSTALLED FOR SPECIAL APPLICATIONS?

The backflow preventer for special applications code 580150, equipped with a captive nut, must be fitted to the cock which thus performs the function of an upstream shut-off valve.

The backflow preventer for special applications 580240/250 must be fitted directly to the pipe, as it is already equipped with an upstream shut-off valve. The connection between valve, fitting and backflow preventer can be blocked with the seal supplied in the package. According to the indications of regulation EN 1717, the backflow preventer is equipped with an inspectable strainer, located in the upstream connection of the body and easily accessible for maintenance, and an adjustable discharge tundish. The appliance must be installed with a downward flow (from top to bottom), respecting the direction of flow indicated by the arrow on the valve body. In the case of particularly dirty mediums, consider installing an additional inspectable strainer upstream.

The pictures below show: Installing the Caleffi 580 backflow preventer for special applications. how to install the Caleffi water backflow preventer for special applications.

DOWNLOAD THE INSTRUCTION SHEET FOR THE BACKFLOW PREVENTER WITH MULTI-FUNCTION GEOMETRY