This section presents several examples of zoned hydronic systems. The hardware used in this system includes many of the devices described in previous sections. These systems show a variety of zoning techniques, sometimes within the same system. They also include provisions for hydraulic separation, air/dirt/magnetic particle separation, purging, pressure regulation, pressure relief and reduced heat migration. They all represent designs that can be constructed using currently available hardware, including many components available from Caleffi North America.

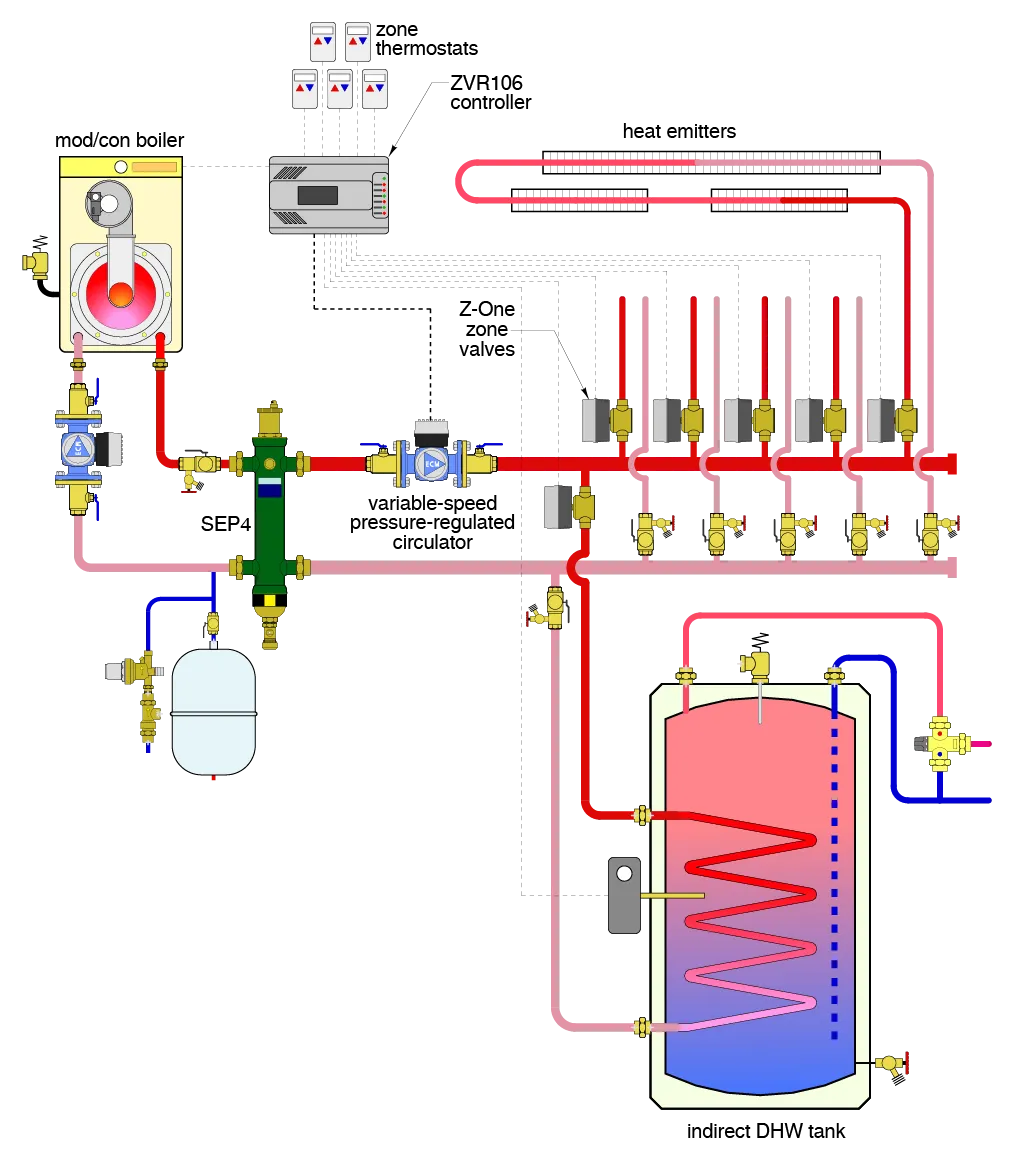

The system in figure 5-1 is a common application in which a single modulating/condensing boiler supplies zoned space heating and domestic hot water.

Domestic water heating is supplied as a priority load. When the aquastat on the indirect water heater calls for heat, the Caleffi ZVR106 controller supplies 24 VAC to the zone valve for the water heater. It also turns on the variable- speed pressure-regulated circulator and signals the boiler to operate at an elevated supply water temperature. The five space heating zones are temporarily prevented from operating, allowing the full boiler heat output to go to the Indirect water heater.

Space heating is supplied by five independent zones, each controlled by a thermostat. When any thermostat calls for heat, the ZVR106 controller opens the associated zone valve. It also turns on the variable-speed pressure- regulated circulator and signals the boiler to operate. The water temperature leaving the boiler is now controlled based on outdoor reset. This keeps the boiler operating at the lowest possible temperature and highest possible efficiency, while still maintaining comfort in the building.

The variable-speed pressure-regulated circulator automatically changes speed based on the number of active zone circuits.

A Caleffi SEP4 hydraulic separator ensures hydraulic separation between the boiler circulator and the distribution circulator. It also provides air, dirt and magnetic particle separation for the system.

All zone circuits and the boiler circuit are equipped with combination isolation and purging valves.

The domestic hot water leaving the tank passes through an ASTM 1017 thermostatic mixing valve to ensure a maximum domestic hot water temperature of 120°F to the plumbing distribution system.

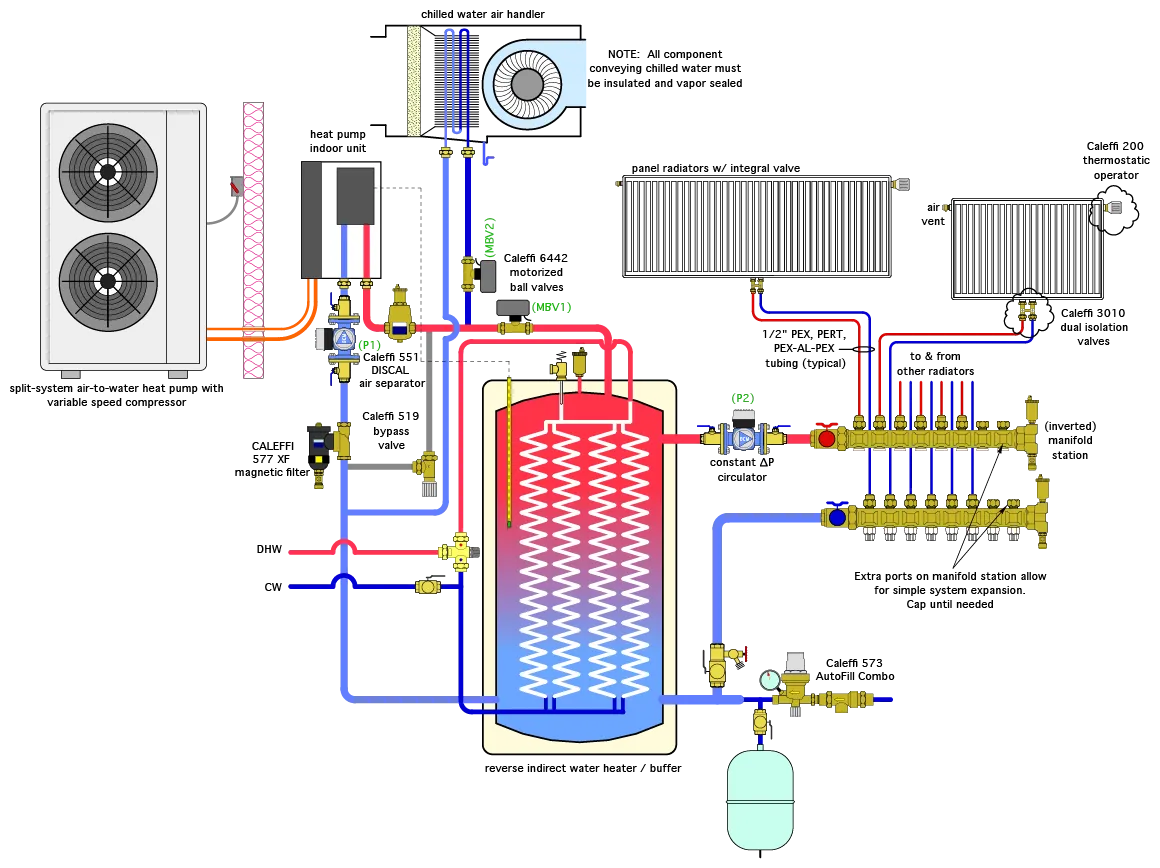

The system in figure 5-2 uses a split system air-to-water heat pump as the heat source for several panel radiators, each with their own thermostatic operator. It also includes a reverse indirect water heater that serves as a buffering mass for the highly zoned distribution system, as well as the system's domestic water heater. A ducted air handler is used for cooling.

When the heat pump is called to operate, in either heating or cooling mode, its circulator runs for one to two minutes prior to the compressor starting. This is a common control function built into air-to-water heat pumps. It's intended to verify proper water flow through the heat pump prior to operating its refrigeration system. During this time, motorized ball valves (MBV1) and (MBV2) are both closed. All flow leaving from the heat pump's indoor unit passes through the differential pressure bypass valve, and then back into the indoor unit. This "holding pattern" prevents water that has not reached a suitable temperature from being injected into the reverse indirect water heater. It also prevents hot water from being temporarily routed to the cooling coil in the air handler as the system transitions from domestic water heating mode to cooling mode.

When the water leaving the heat pump's indoor unit has reached a suitable temperature for heating, motorized ball valve (MBV1) opens, allowing flow into the upper portion of the reverse indirect water heater. The bypass valve closes as soon as (MBV1) opens.

During heating mode, the heat pump monitors the temperature of the reverse indirect water heater, keeping it between 115 and 125°F. This is typically high enough for adequate domestic water heating as cold water makes a single pass through the large internal heat exchanger coils. It's also hot enough to provide design load output through properly sized panel radiators.

During the heating season, the variable-speed pressure- regulated circulator (P2) operates 24/7 in constant differential mode. Its speed automatically adjusts as the thermostatic radiator valves on the panel radiators open, close or modulate flow.

Each panel radiator has an integral valve. Those valves are fitted with Caleffi 200 thermostatic operators, making each of the radiators an independently controlled zone. Each radiator is also equipped with a Caleffi 3010 dual isolation valve.

During cooling mode, the heat pump circulator (P1) starts and operates for up to two minutes before the refrigeration system begins cooling the water. During this time, motorized ball valves (MBV1) and (MBV2) remain closed. Flow passes through the differential pressure bypass valve and back to the heat pump. When the water leaving the heat pump has reached a suitable temperature for cooling, (typically 45 to 55°F), motorized ball valve (MBV2) opens, allowing chilled water flow to the coil in the air handler.

All piping and components that convey chilled water are insulated and vapor sealed to prevent condensation.

The controls for this system would prioritize domestic water heating over cooling if both modes became active at the same time. During warm weather, when cooling is often required, the heat pump can heat the tank from 115 to 125°F in a few minutes and then allow the system to switch back to cooling.

This system is relatively simple. It only requires two circulators. Still, it provides multi-zone space heating, single zone cooling and domestic water heating.

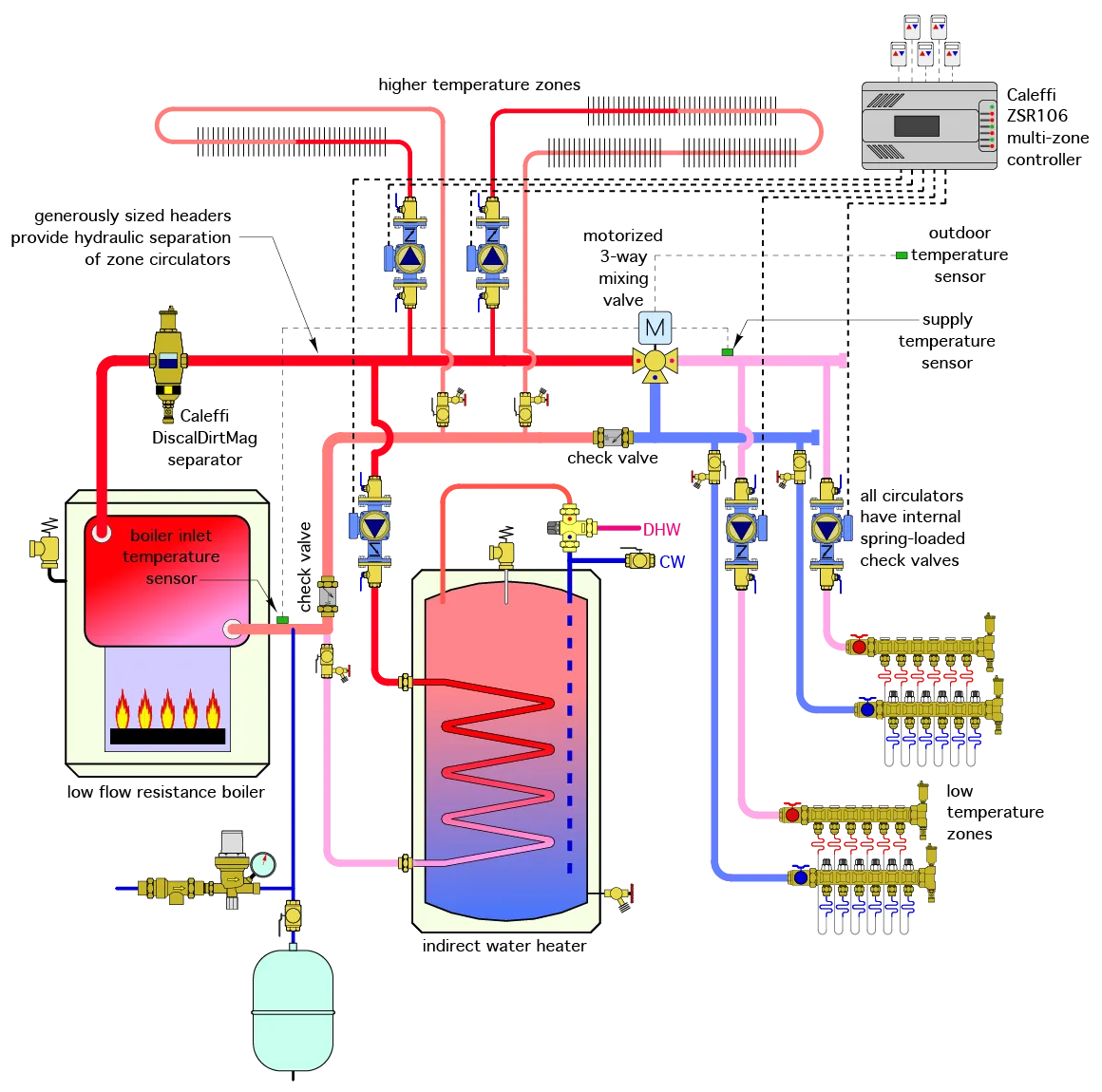

The system in figure 5-3 supplies multi-zone space heating and domestic water heating from a conventional boiler.

Two of the space heating zones serve higher-temperature heat emitters, such as fin-tube baseboard, convectors or fan-coils. The other two zones serve low-temperature radiant panel circuits.

A 3-way motorized mixing valve is used to control the supply water temperature to the radiant panel circuits based on outdoor reset control. The controller operating this mixing valve also monitors the boiler's inlet temperature. When necessary, it reduces hot water flow into the mixing valve to maintain the boiler inlet temperature at or above 130°F whenever possible. This protects the conventional boiler from sustained flue gas condensation.

Note that a check valve is required on the return side of the low-temperature piping to prevent the possibility of reverse flow through the mixing valve when either of the circulators for the higher-temperature zones are operating. Another check valve is used to minimize heat migration into the return header when the indirect water heater is operating. This is especially helpful in warm weather, when uncontrolled heat loss from piping adds to the building's cooling load.

Domestic hot water is provided by an indirect water heater, which is operated as a priority load. The piping serving the indirect water heater is kept close to the boiler to minimize piping heat loss. The combination of the low-flow-resistance cast iron boiler and generously sized header piping provides adequate hydraulic separation between simultaneously operating circulators.

The Caleffi DISCALDIRTMAG™ separator handles all air, dirt and magnetic particle collection for the system. Purging valves are provided on the return side of each zone circuit and the circuit supplying the indirect water heater.

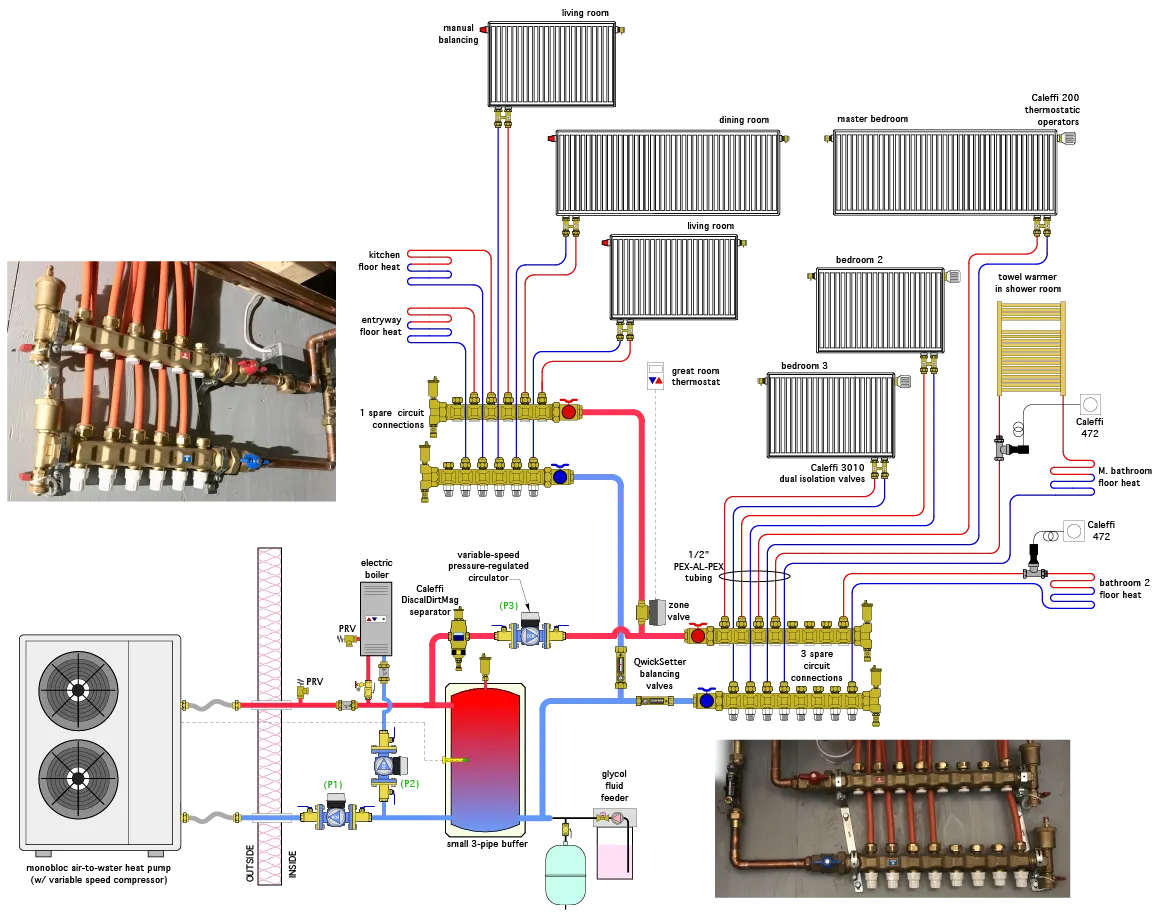

The system shown in figure 5-4 is based on a real installation. It uses a monobloc air-to-water heat pump as its primary energy source. An electric boiler is included for supplemental and back up heat if needed. Two homerun distribution subsystems are used to meet specific project zoning requirements.

During the heating season, the heat pump continually monitors the temperature of a small buffer tank. The heat pump controls are set to maintain the tank temperature based on outdoor reset control, with an upper temperature limit of 120°F at design load conditions.

When necessary, the heat pump signals the electric boiler and its associated circulator to operate for supplemental heat input to the buffer tank.

The home this system is installed in has a large open area that includes the kitchen, dining room and living room. This area is treated as a single zone. It's heated by three panel radiators and two floor heating circuits all supplied from a single manifold station, and thus, all operate at the same water temperature. Flow to this manifold station is controlled by a single zone valve operated by an electronic thermostat.

The three bedrooms and two bathrooms are each controlled as separate zones using two types of thermostatic valves. The three bedrooms each have a panel radiator equipped with integral valve regulated by a thermostatic operator. One bathroom has a single floor heating circuit. Flow through that circuit is controlled by a Caleffi 472 thermostatic valve with wall-mounted setting dial. The master bathroom has a towel warmer radiator in the shower area, as well as floor heating. The towel warmer and floor circuit are connected in series and are also controlled by a Caleffi 472 thermostatic operator with a wall-mounted setting dial. The 472 thermostatic operators are mounted to Caleffi 221 radiator valves that can be accessed from the basement.

Flow through the entire distribution system is provided by a single variable-speed pressure-regulated circulator that only requires 44 watts of electrical input when operating at full speed, and often at 20-25 watts under part-load conditions. This circulator operates 24/7 during the heating season.

The entire system operates with a 30% solution of propylene glycol antifreeze. An automatic fluid feeder is used to maintain system pressure. This system demonstrates that several types of zoning hardware (thermostatic and motorized) can be combined to meet project requirements. It's also a system that could be expanded, initially or in the future, to include chilled water cooling through an air handler, as well as domestic water heating.

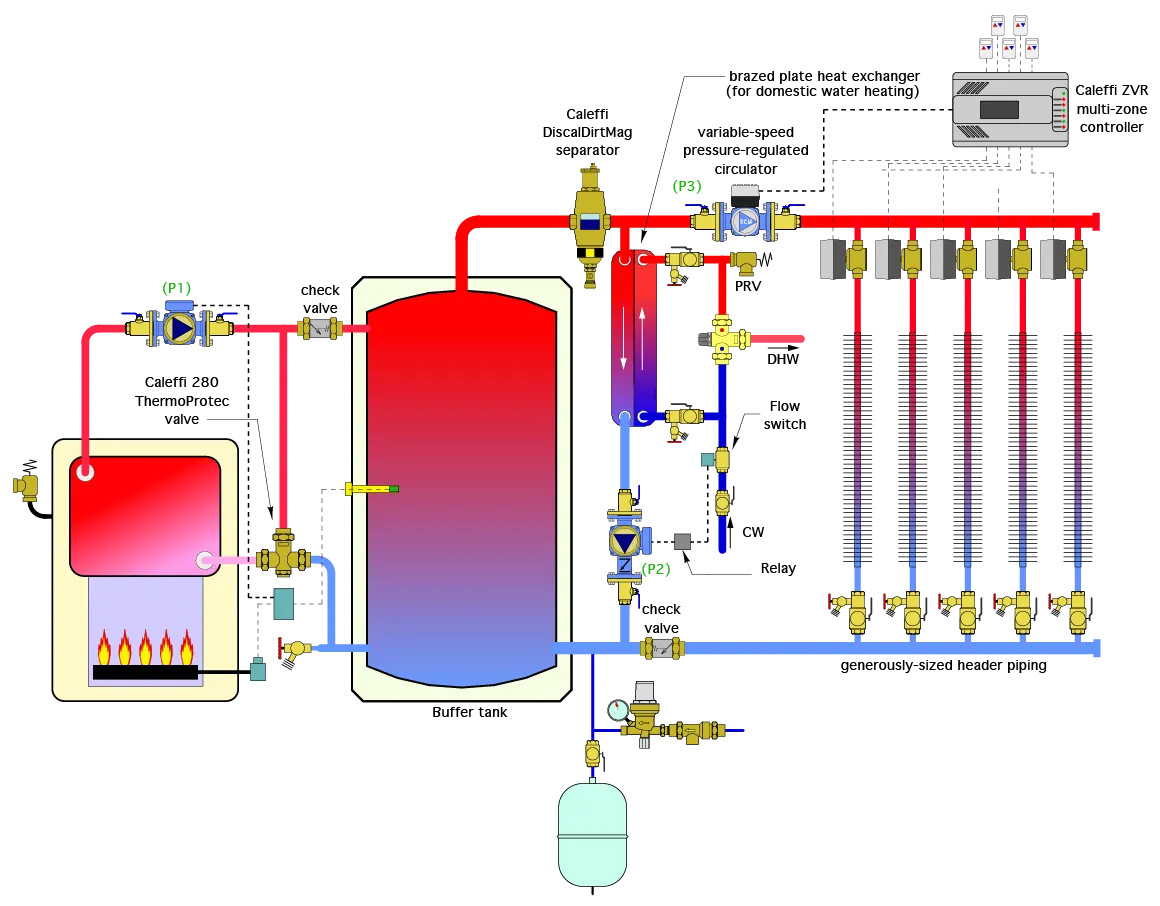

The system in figure 5-5 uses a conventional gas-fired cast iron boiler to supply five zones of high-output fin-tube baseboard. It also includes a brazed plate stainless steel heat exchanger that provides on-demand domestic hot water.

A setpoint temperature controller continually monitors the temperature of the buffer tank. It fires the boiler as necessary to maintain the tank temperature in the range of 120 to 160°F.

The boiler is protected against sustained flue gas condensation by a Caleffi 280 ThermoProtec™ mixing valve, which keeps the boiler inlet temperature at or above 130°F whenever possible.

When any of the five space-heating thermostats call for heat, the Caleffi ZVR106 Multi-Zone Valve Control operates the associated zone valve(s) and turns on the variable-speed pressure-regulated circulator. The circulator automatically adjusts its speed to maintain constant differential pressure as the zone valves open and close.

The heat emitters are high-output fin-tube baseboard sized to provide design heating load at a supply temperature of 140°F.

Domestic water is heated "on demand" using heat stored in the thermal mass of the buffer tank. Whenever there's a draw from a hot water fixture of 0.7 gallon per minute or more, the flow switch closes its contacts to power the coil of a relay, which turns on circulator (P2). Hot water from the upper portion of the buffer tank passes through the primary side of the brazed plate heat exchanger as domestic water passes in counterflow through the other side.

The heat exchanger has been sized so that it can supply 115°F domestic water when the input water from the tank is 120°F. A Caleffi 521 MixCal valve limits domestic hot water delivery temperature to 120°F. The heat exchanger is equipped with two combination isolation/flushing valves. These allow the domestic water side of the heat exchanger to be isolated and periodically flushed with a mild acid solution to dissolve and remove possible scaling.

A spring-loaded check valve in the return header minimizes heat migration into space-heating piping during non- heating months when the tank is being heated solely to produce domestic hot water. Another check valve near the upper left piping connection of the buffer tank prevents reverse thermosiphon flow through the boiler when it is off.

Other details include:

• A Caleffi DISCALDIRTMAG® separator to handle air, dirt and magnetic particle separation.

• Purging valves at the return side of each zone circuit.

• Automatic feed water assembly with pressure-reducing valve and backflow preventer.

• A pressure relief valve on the domestic water side of the heat exchanger.