DIRTMAG®PRO, Technopolymer dirt separator with double magnet for high flow rates.

Product Description

Technopolymer dirt separator with double magnet for high flow rates.

Adjustable for horizontal or vertical pipes.

Drain cock with hose connection.

Technical data

Download

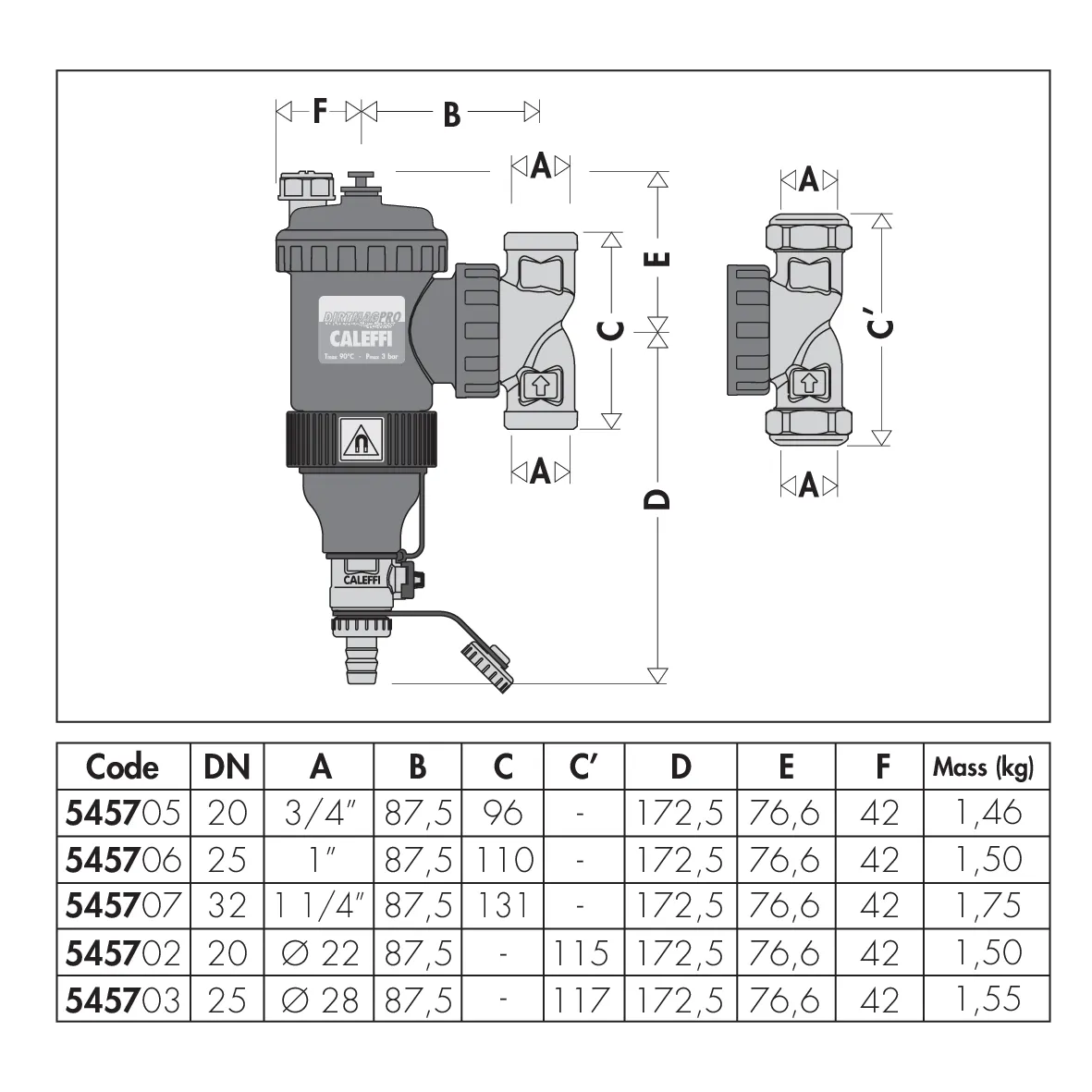

Drawings and specifications

| Part number | Connection | Maximum recommended flow rate | |

|---|---|---|---|

| 545705 | G 3/4" (ISO 228-1) F |

1,6 m³/h | |

|

2D drawings

3D models

Tender text

CALEFFI, 545705, DIRTMAG®PRO.

Technopolymer dirt separator with double magnet for high flow rates.

Adjustable for horizontal or vertical pipes.

Drain cock with hose connection. Connection: G 3/4" (ISO 228-1) F. Maximum working pressure: 3 bar. Medium temperature range: 0–90 °C. Maximum recommended flow rate: 1,6 m³/h. Material: technopolymer.

SCIP code

3017016c-fa83-4f9e-a046-f80e60b5e0ce

|

|||

| 545706 | G 1" (ISO 228-1) F |

1,8 m³/h | |

|

2D drawings

3D models

Tender text

CALEFFI, 545706, DIRTMAG®PRO.

Technopolymer dirt separator with double magnet for high flow rates.

Adjustable for horizontal or vertical pipes.

Drain cock with hose connection. Connection: G 1" (ISO 228-1) F. Maximum working pressure: 3 bar. Medium temperature range: 0–90 °C. Maximum recommended flow rate: 1,8 m³/h. Material: technopolymer.

SCIP code

327e76e0-23e7-412a-9dee-3fbae9fa6e6b

|

|||

| 545707 | G 1 1/4" (ISO 228-1) F |

2,6 m³/h | |

|

2D drawings

3D models

Tender text

CALEFFI, 545707, DIRTMAG®PRO.

Technopolymer dirt separator with double magnet for high flow rates.

Adjustable for horizontal or vertical pipes.

Drain cock with hose connection. Connection: G 1 1/4" (ISO 228-1) F. Maximum working pressure: 3 bar. Medium temperature range: 0–90 °C. Maximum recommended flow rate: 2,6 m³/h. Material: technopolymer.

SCIP code

b4f76fe0-38a5-4c40-86bc-e5edb8dec727

|

|||

| 545702 | Ø 22 |

1,6 m³/h | |

|

2D drawings

3D models

Tender text

CALEFFI, 545702, DIRTMAG®PRO.

Technopolymer dirt separator with double magnet for high flow rates.

Adjustable for horizontal or vertical pipes.

Drain cock with hose connection. Connection: Ø 22. Maximum working pressure: 3 bar. Medium temperature range: 0–90 °C. Maximum recommended flow rate: 1,6 m³/h. Material: technopolymer.

SCIP code

ab9fb739-80be-4819-b5a7-8874cc82f81d

|

|||

| 545703 | Ø 28 |

1,8 m³/h | |

|

2D drawings

3D models

Tender text

CALEFFI, 545703, DIRTMAG®PRO.

Technopolymer dirt separator with double magnet for high flow rates.

Adjustable for horizontal or vertical pipes.

Drain cock with hose connection. Connection: Ø 28. Maximum working pressure: 3 bar. Medium temperature range: 0–90 °C. Maximum recommended flow rate: 1,8 m³/h. Material: technopolymer.

SCIP code

3aa2b7b1-28cb-45b8-96b1-4e9bf75ab9e5

|

|||

Faq - Frequent questions

What are the effects of contamination in plants?

The most common effects of contamination of heating and cooling systems include:

electrochemical corrosion - the deposition of contaminants on the metal components of the system leads to the formation of two zones (water/contaminants and contaminants/metal) with different oxygen contents. Due to this, an anodic reaction also occurs, leading to corrosion of the metal surfaces.

Valve malfunctioning - impurities in the water are deposited on the valve components, resulting in reduced control properties and leakage.

Reduction in heat exchanger efficiency - the accumulation of impurities in the heat exchanger reduces the heat transfer surface and restricts the flow of the medium.

Damage to the pump - impurities flowing into the pump can accumulate on pump components and cause damage to the internal structures and magnetic fields generated by the unit.

What are the causes of contamination in the heating and cooling system?

The first significant risk factor is the presence of impurities in the system water. This type of impurity can occur if the system has not been sized correctly or if all impurities have not been carefully removed from the system and the system must be cleaned. The presence of impurities can lead to clogged circulation pumps, reduced efficiency of heat exchangers or malfunctioning valves and poor heat transfer.