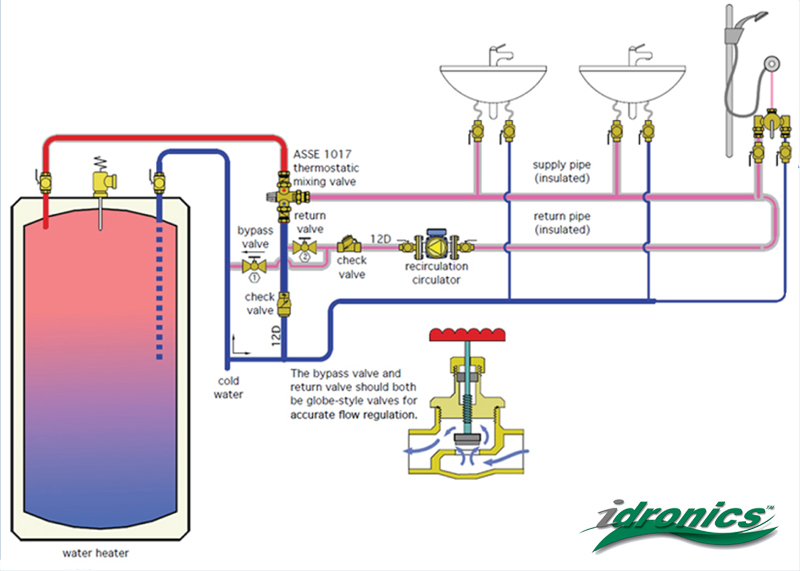

We get a lot of tech support calls asking about proper piping of a point-of-distribution master mixing valve when a domestic hot water system has a recirculation pump. Unfortunately, there are a LOT of incorrectly piped systems out there, resulting in either temperature creep or temperature droop in the recirculation piping at night when there is no draw from fixtures. The first hot water users in the morning can have overheated (creep) or underheated (droop) hot water when the system is not piped like we show in Caleffi idronics™ journal (Issue #11), Figure 7-5, or in the Installation Instructions for our 521, 5231 Series MixCal™ or 6000 Series LEGIOMIX® valves.

Here are some short answers (see those literature references for details) to common temperature creep and temperature droop questions:

1) Make sure there is always enough flow to meet the valve minimum flow GPM requirement. All control valves need enough flow to work properly. A correctly sized, constantly running recirculation pump will usually assure enough flow.

2) A master point-of-distribution mixing valve that does not have 100% close-off on it's inlet ports (most thermostatic mixing valves) can cause creep or droop if not properly piped. Most digital mixing valves, such as the 6000 Series LEGIOMIX, have 100% close-off, so creep and droop are a non-issue.

3) Figure 7-5 in idronics #12 shows proper piping with a return valve, which throttles the amount of recirculation water going back to the cold inlet of the mixing valve, and a bypass valve which throttles the amount of recirculation water going back to the storage tank. These valves can be simple valves, like the Caleffi 142 Series Flo-Set™. The bypass valve needs to be open only slightly, allowing only enough recirculation water to flow back to the tank and out to the mixing valve hot inlet in order to make up for the heat losses in the supply piping going out to the fixtures. Page 54 in idronics #11 describes how to set that up. The return valve is typically fully open (sometimes not even needed). Too much water going back to the storage tank causes creep; too little causes droop. These valves balance out the return flows.

Check out those piping schematics, and if you need more help contact us!

ARE THE 2 VALVES STILL REQUIRED IF USING A MASTER MIX VALVE AND THERMOSTATIC BALANCE VALVES?

In reply to ARE THE 2 VALVES STILL by MARK CHARLAND

Mark, if a master mixing valve does not close off tight at the hot inlet port, you need those 2 "balancing" valves to minimize the amount of hot water going back to the storage. Many master (ASSE 1017) thermostatic mixing valves do not close off 100% (Caleffi's 521 and 5231 Series, for example). Some do, for example our 520 Series and our 6000 Series LEGIOMIX electronic mixing valve; they close off tight to prevent creep.

In reply to Mark, if a master mixing by tech_support

So after looking it up I installed a 520 series Anglemix on a job, still experiencing temperature creep.

In reply to So after looking it up I by Marty Lappin

Marty, our 1/2" and 3/4" (small body) model 520 series mixing valves can close off the hot completely. Our 1" (large body) models do not. If you installed a small body and are still experiencing this, it is possible that there is debris or buildup in the body preventing complete hot closure.

We have an air vent for our boiler.

On it is "10 bar 115C Caleffi Made in Italy"

Imprinted in black is "1514"

Photo attached.

The air is not venting.

Is there a way to manually vent it?

If not, please suggest what we can do.

Thank you.

Mindy,

That is a 5026 Series air vent, our 502610A model. It does not have a manual method of venting the air. Make sure the cap is not screwed down tight; it is designed to be partially unscrewed to allow the air to escape. If it is, the vent hole is is probably clogged with debris and you should replace it.

I recently installed Buderus G115 w/Logamatic and a 30 gal. DHW indirect tank. I have 5 circ pumps and 4 zones in my home.

During he last cold wave the hot water boiler was short cycling constantly. I would like to add a buffer tank but feel that

having 2 tanks would be less efficient. Also I'm not sure how the Logamatic control would affect the system. Thanks in

advance for any input to this situation.

In reply to I recently installed Buderus by Joe Johnson

Hi Joe,

That is a very clean installation!

Having two tanks will not reduce efficiency. Adding a buffer tank will help to keep the boiler from short cycling during demands from very small zones. Buffer tanks are not typically used in high mass boilers like your cast iron model but it will really depend on the size of the smallest zone.

We have a technical journal on this very topic that may help you. https://www.caleffi.com/sites/default/files/coll_attach_file/idronics_1…

I would recommend working with your contractor to determine if there may be another problem causing the short cycling and if a buffer tank is necessary.

Best Regards,

Cody Mack

Caleffi North America

hi. i have a schuco solar hot water system and the same controller as in your youtube video - iSolar controller. the temp in the tank, as measured, all of a sudden does not go above about 60degrees even when solar temp is 200. thoughts? could it be a sensor not working?

am i correct that the temp in the tank may be much higher but a sensor problem has the reading as 60? thank you.

Sam,

That could be the issue. We cannot be sure because the Schuco controller may function differently compared to the Caleffi iSolar controller (even though they look similar).

I am installing a wifi shut off valve on water main for leak protection when not home, therefore it seems necessary to install an expansion tank. What placement (figure 7-5 in idronics 12) would you recommend?

Hi Bart,

Thank you for your question. I would recommend discussing this application with your WiFi valve supplier, local plumber or plumbing designer to the installation requirements that fit their product specs. and local plumbing codes. If you need additional products relating to temperature control, pressure control or check valves to get this product installed properly please contact us to help you select from our product offerings.

Best Regards,

Dan Firkus

Caleffi North America

Hello, I need a temperature controller for the recalculation pump for a hot water distribution system that works in a 4 stories villa with 900 (3x300) liter/day thermosyphon heat pipes solar water heaters that are hydraulically connected in a balanced way as a central system on the roof top of the villa. We need the temperature controller for the re-circulation pump that keep the water moderately hot in the distribution system to the final point of hot water consumption. Please advise on proper reliable product. I do not need the differential temperature controller as it is not designed for such a function. I understand that it is used for forced circulation solar water heating systems. Thanks for your anticipated reply.

We are installing small central solar water heating systems in multi story villas and buildings. We normally use re-circulation pumps for keeping the hot water 24 hours near by the points of extraction (consumption) in the buildings.

We need the temperature controller that works on a set-on law temperature (pump starts to go on) to circulate the water until reaching a set-off higher temperature to stop the pump to avoid higher thermal losses or temperature creep.. I also believe that the differential temperature controllers used for forced solar water heating systems would not be a adequate for such a particular situation.

Please advise on the simplest reliable and proper controllers available among your products for this re-circulation pump optimal operation.

Thanks a lot for your anticipated reply>

Adel Beshara

https://www.linkedin.com/in/adel-beshara-a777a4ab/

In reply to We are installing small by Adel Beshara

Hello Adel,

Thank for contacting us and this is a combined response to your two posts above. First we do not offer an electronic control or aqua-stat that will control a domestic water re-circulation pump. We take a different approach and i would refer you to our Idronics issue 21 on "Recirculating Domestic Hot Water Systems". As you design your domestic re-circulation system we offer a lot of products for example our 6000 Legio-Mix electronic mixing valve to control domestic water outlet temperatures at the point of distribution and has 100% close off to eliminate creep. You describe your project as a multi story building. We have options for balancing domestic water circuits or branch runs. Our 116 ThermoSetter for example would provide thermostatic balancing to the branch circuits to ensure to increase the speed of hot water delivery, reduce water waste and save pump energy. The above options with today's energy efficient pumps may be a great solution. I would always encourage you to reference our Idronics or you can see our "Coffee with Caleffi" webinars on YouTube. We have webinars on there that relate to domestic water recirculation. You can access either of the two through the "Education" tab on our website.

Best Regards

Dan Firkus

Caleffi North America

What prevents returned mixing water from getting into the cold system?

Pete,

It's important to install check valves into cold water line to prevent any mixed water from pushing back in to the cold or creating a cross conneciton in your plumbing system.

when water usage is not happening what did i adjust to keep the temp. Around 120. The mixing valve or the return valve. Then when water is being used, which valve should I adjust?

Thanks

Damian,

You will want to have the recirculation return line piped to the cold side of the mixing valve with the bypass return to the tank. It valve to the tank should be opened to allow it to bypass to the tank but with enough restriciton to send most of the return water throught the mixing valve to maintanin a stable mixed outlet temperature. If you send the return water through the tank and not the cold side or have too much bypass through the tank and you may see the mixed outlet temperature "Creep" above the desired setting. We recommend globe valves be used for control the flow the flow to the tank. Once the system is set up you usually will not need to make changes in how it is balanced.

Hi I have a Recirculation Line Returning into the cold water inlet and into my Mixing valve do I need a Check Valve before the Mixing valve as Temps Spike ?

Michael, I would make sure you have the globe valve on the bypass back to the cold line into the tank to create restriction to direct the flow through the mixing valve. If that bypass valve is missing or open the path of least resistance will be through the tank that will push the mixed outlet temperature above desired set point.

What causes a spike in temp in the return line in a commercial building?

In reply to wat causes a spike in temp in by david reeves

David, Usually hot water temperature that is elevated above design temp is called temperature "Creep". It is commonly seen when the recirc. return line is not correctly piped back to the mixing valve and heater or when the system is not balanced correctly.

I have read that a recirculation line should be run at 140 degrees to kill bacteria such as legionella what is your opinion on this I see In one of your diagrams you use a mixing valve at the hot water tank and recirculate the water at a tempature of 120 would that not promote bacterial growth I. The line or would a continuous recirculating pump stop it because water is not stagnate

In reply to I have read that a by Nathan

Nathan, You are correct that elevating the recirc temperature to 140F is used to manage Legionella bacteria. It is a process called Thermal Disinfection. Thermal Disinfection requires safety devices at each fixture and a way to manage and confirm the process. Your normal recirc temperature will be whatever the tank is set for or the temperature of the master mixing valve minus system heat loss. It needs to be maintained at a safe temperature to prevent scalding. You can elevate the hot water and recirc temperature if you have point of use mixing valves at each fixture to protect the end user.